- Understanding the Role of Geomembrane Liners in Waste Management

- Innovations in Geomembrane Liners for Water Management

- Geomembrane Liners: A Comprehensive Guide

- The Future of Geomembrane Liners in Civil Engineering

- Geomembrane Liners: Enhancing Landfill Stability

Manager:

WhatsApp:+86 177 0135 2670

Tel:+86 177 0135 2670

Email:marketing@okorder.com

Address:3rd Floor, No.2 Building, No.1 Sanlihe Road

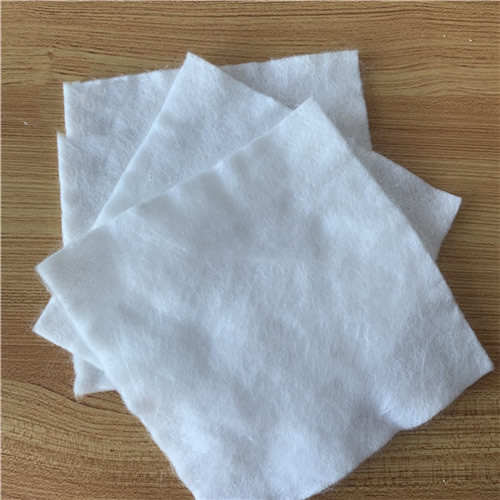

Polypropylene Filament Geotextile

Product Categorie:Geotextiles

Product number:N152

Product Color:Optional

Product Sources:Suppliers & Manufacturers

The polypropylene industry used in the preparation of filament Geotextiles will be used like spider webs for the separation of filaments. The key to preparing polypropylene filament geotextiles is to separate the filaments, that is, pull a bunch of filaments out of the yarn tube and put them into the fiber mesh. The greater the degree of separation, the more uniform the formation of the fiber web and the better the product quality.

Analysis of influencing factors of polypropylene filament geotextiles

The greater the wind pressure, the better the separation effect, but the separation effect is not significant. The wind pressure increased from 0.4kpa to 0.7kpa, and the separation ratio decreased from 8% to 7.5%. The reason is that wind pressure can blow away the filament, but it can also drive the filament to rotate, which is not conducive to separation. In addition, the higher the voltage, the better the splitting effect, but when the voltage increases to a certain value, the effect of increasing voltage on the splitting effect is no longer significant. This is because the greater the voltage, the greater the electric field strength, the greater the power of the optical fiber, and the better the splitting effect. When the capacitance of the fiber is saturated, increasing the voltage has little effect on the separation effect of the fiber.

- Previous:no more

- Next:Pet Filament Geotextile