- Understanding the Role of Geomembrane Liners in Waste Management

- Innovations in Geomembrane Liners for Water Management

- Geomembrane Liners: A Comprehensive Guide

- The Future of Geomembrane Liners in Civil Engineering

- Geomembrane Liners: Enhancing Landfill Stability

Manager:

WhatsApp:+86 177 0135 2670

Tel:+86 177 0135 2670

Email:marketing@okorder.com

Address:3rd Floor, No.2 Building, No.1 Sanlihe Road

The Role of Geomembrane Liners in the Management of Industrial Byproducts

Geomembrane liners, also known as high-density polyethylene (HDPE) liners, are a crucial component in the management of industrial byproducts. They are used to contain hazardous waste, protect the environment, and prevent contamination of soil and groundwater. These liners are made from a variety of materials, including polymers, bitumen, and clay, and are designed to be flexible, durable, and resistant to chemicals.

The Importance of Geomembrane Liners

Geomembrane liners play a vital role in the management of industrial byproducts. They are used to create a barrier between the waste and the surrounding environment, preventing the spread of contaminants. This is particularly important in industries such as mining, where large amounts of waste are generated, and there is a risk of contamination to nearby water sources.

How Geomembrane Liners Work

Geomembrane liners work by creating a physical barrier between the waste and the environment. They are designed to be impermeable, meaning that they do not allow liquids or gases to pass through. This is achieved through the use of a dense, continuous material that is resistant to the chemicals and substances found in industrial byproducts.

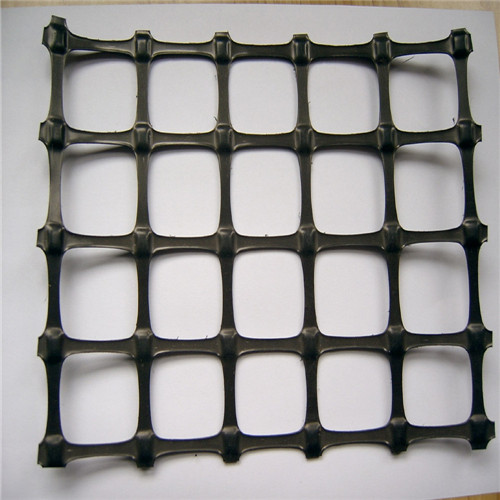

Types of Geomembrane Liners

There are several types of geomembrane liners available, each with its own unique properties and applications. Some of the most common types include:

- High-Density Polyethylene (HDPE) Liners: These liners are made from a tough, durable plastic and are resistant to a wide range of chemicals. They are commonly used in landfills and waste containment facilities.

- Polyvinyl Chloride (PVC) Liners: PVC liners are flexible and resistant to UV radiation, making them ideal for outdoor applications. They are often used in ponds and reservoirs.

- Clay Liners: Natural clay liners are an environmentally friendly option, providing a natural barrier to contaminants. They are often used in smaller-scale projects, such as landscaping and gardening.

- Bituminous Liners: These liners are made from bitumen, a type of asphalt, and are known for their flexibility and resistance to punctures. They are commonly used in canal lining and other large-scale projects.

Benefits of Using Geomembrane Liners

Using geomembrane liners offers a number of benefits, including:

- Environmental Protection: By preventing the spread of contaminants, geomembrane liners help to protect the environment and preserve natural resources.

- Cost-Effectiveness: Geomembrane liners are a cost-effective solution for waste containment, as they require less maintenance and have a longer lifespan than other types of liners.

- Durability: These liners are designed to withstand harsh conditions and are resistant to UV radiation, chemicals, and punctures.

- Flexibility: Geomembrane liners can be easily molded to fit the contours of the land, making them suitable for a wide range of applications.

- Customizability: They can be tailored to meet the specific needs of a project, including size, thickness, and material composition.

Challenges in Implementing Geomembrane Liners

Despite their many benefits, there are also some challenges associated with the implementation of geomembrane liners. These include:

- Installation Complexity: Installing a geomembrane liner can be a complex process, requiring specialized equipment and expertise.

- Cost: While they are cost-effective in the long run, the initial cost of purchasing and installing a geomembrane liner can be high.

- Maintenance: Although geomembrane liners are low-maintenance, they still require regular inspections to ensure that they are functioning properly and to detect any potential issues early on.

- Compatibility: It is important to ensure that the liner is compatible with the waste materials it will be in contact with, as some chemicals can degrade certain types of liners.

The Future of Geomembrane Liners

As industries continue to grow and generate more waste, the need for effective waste management solutions will only increase. Geomembrane liners are likely to play a significant role in this, as they offer a reliable and environmentally friendly way to contain and manage industrial byproducts. Advancements in materials and manufacturing techniques are expected to lead to the development of even more durable and efficient liners in the future.

Personal Touch

In conclusion, geomembrane liners are an essential part of our efforts to manage industrial byproducts responsibly. They not only protect our environment but also ensure that we can continue to develop and grow without compromising the health of our planet. It's a fascinating world of engineering and environmental science, where every liner laid down is a step towards a cleaner, safer future.

- Previous:Geomembrane Liners: A Barrier Against Industrial Chemicals

- Next:Geomembrane Liners: A Solution for Containing Industrial Spills

-

2024-12-05Geomembrane Liners: A Comprehensive Guide