- Understanding the Role of Geomembrane Liners in Waste Management

- Innovations in Geomembrane Liners for Water Management

- Geomembrane Liners: A Comprehensive Guide

- The Future of Geomembrane Liners in Civil Engineering

- Geomembrane Liners: Enhancing Landfill Stability

Manager:

WhatsApp:+86 177 0135 2670

Tel:+86 177 0135 2670

Email:marketing@okorder.com

Address:3rd Floor, No.2 Building, No.1 Sanlihe Road

A Personal Exploration of 40 Mil HDPE Geomembranes’ Strength and Versatility

In the wide world of geosynthetic materials, it’s amazing how this 40 mil hdpe Geomembrane grabs attention as a symbol for toughness and adaptability. They are liners that go beyond just being barriers to testing our commitment to environment friendliness as well as engineering prowess. This article is a personal journey through the world of 40 mil HDPE geomembranes, capturing their essence, applications, and the technical nuances that make them an industry staple.

The Protective Layer: 40 Mil HDPE Geomembranes

A liner made from a 40 mil HDPE geomembrane is a fragile yet strong layer that serves as a barrier against fluid migration, gas flow-through or contaminant seepage. These liners are integral aspects in environmental engineering and geotechnical projects that deal with containment and pollution prevention issues.

Applications: A Spectrum of Utility

Painting many uses opens up one among these forty mile hdpe geomembranes ideas. For they’re found in landfill liners, mining applications, erosion control measures, agricultural lagoons,, oil retention areas decorative ponds-stormwater retention ponds-irrigation canals-tunnels-below grade structures-waste lagoons-secondary containment-floating covers. Every specific case serves as evidence regarding pliability and dependability for such types of geomembranes.

Material Marvel: High-Density Polyethylene (HDPE)

High density polyethylene (HDPE) is selected by many manufacturers as the material for their 40mil liners because it has excellent attributes. It has high tensile strength which ensures no breaking or piercing can take place even with ground movements or non-uniform surfaces. The material also resists UV degradation highly which makes its good for outdoor durability over time.

Key Properties and Considerations

Choosing appropriate thicknesses, formats, textures, certified properties, fabricated shapes and project scale are among the criteria for selecting the right 40 mil HDPE geomembrane. For instance, a forty-mil thickness balances price benefit against puncture resistance as it can be applied to a wide variety of uses.

Installation Best Practices

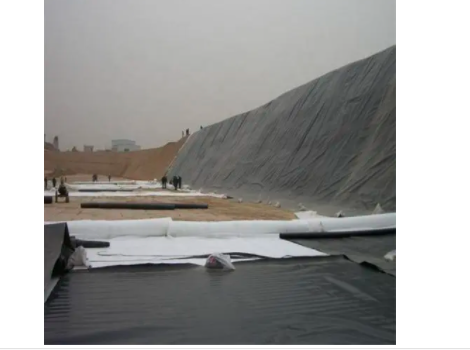

The installation of 40 mil HDPE geomembrane liners is a delicate dance of precision and planning. It involves site preparation, deployment, field seaming, anchoring, pipe boots, protective layers and rigorous quality assurance/quality control measures. In order for the liner to perform well over extended timeframes every step counts.

The Advantages of HDPE Geomembrane Liners

Non-reactivity chemically resistant durable flexible impermeable strong and UV resistant are some advantages associated with HDPE geomembranes. These characteristics make them an excellent choice for long-term environmental containment projects.

ASTM Standards: The Blueprint for Quality

To guarantee quality as well as performance in this regard all HDPE geomembranes have to meet certain set industry standards by ASTM international that act like blueprints for quality covering material properties physical parameters and testing procedures.

Geotechnical Engineers: The Guardians of Quality

Geotechnical engineers play a pivotal role in the installation of HDPE liner systems. They provide expertise in evaluating subsurface conditions, ensuring proper subgrade preparation, and designing anchoring solutions that are critical for the success of liner containment systems.

UV and Chemical Resistance: Dual Shields of Protection

HDPE geomembranes are designed to withstand damage from ultraviolet (UV) radiation since they can be exposed to sun rays. Their chemical resistance ensures they maintain barrier performance even when exposed to aggressive chemicals.

Thicker Liners for Enhanced Durability

While 40mil liners balance protection with cost effectively selecting thicker liners such as 60 or 80 mils could offer additional protection durability longer life especially during crucial containment applications.

Conclusion: The Everlasting Relevance of 40 Mil HDPE Geomembranes.

Finally, it is worth noting that 40 mil HDPE geomembrane liners stand for more than just a form of protection in the form of a thin film, but also they are proof of our material science genius and commitment to environmental stewardship. These liners will always be the most crucial tool as we try to have sustainable development and protect the environment because they can be changed to serve other purposes.

The study has given an opportunity to look at this in relation to 40 mil HDPE geomembrane liner’s usage. Consequently, let us grow in technological innovation and responsibility as we use them as stepping stones towards creating a tomorrow which is self-sufficient both for our future generation’s requirements and nature. It implies that “geomembrana hdpe 40 mils” signifies the same thing that we all wish for; an environment that is safe from danger or harm.

This personal inquiry into 40 mil HDPE geomembranes was eye-opening because it illustrates advances made through materials engineering ingenuity and dedication to ecological preservation. In addition, these reasons should always be remembered when talking about these liners in relation with the search for sustainable development and environmental protection. So many possibilities lie ahead with each one being a chance; therefore, the said geomembranes can work as agents of change contributing significantly towards our objectives and that of Mother Nature.

- Previous:Comprehensive Study of a 30 mil Geomembrane Liner as an Armor Plate

- Next:Passionate Pursuit and Science of HDPE Geomembrane Welding