- Understanding the Role of Geomembrane Liners in Waste Management

- Innovations in Geomembrane Liners for Water Management

- Geomembrane Liners: A Comprehensive Guide

- The Future of Geomembrane Liners in Civil Engineering

- Geomembrane Liners: Enhancing Landfill Stability

Manager:Alvin Wang

WhatsApp:+62 8983806051

Tel:+86 10-5797-1075

Email:steelwang@okorder.com

Address:3rd Floor, No.2 Building, No.1 Sanlihe Road

HDPE Geomembranes: The Essential Component for Ponds in Oil and Gas Ponds

Ponds are a common sight in oil and gas operations, serving as a crucial part of the infrastructure. But what makes these ponds so effective and efficient? The answer lies beneath the surface, in the form of hdpe Geomembranes. These versatile and robust materials are the unsung heroes of pond construction, providing a reliable barrier that keeps the environment safe and the operations running smoothly.

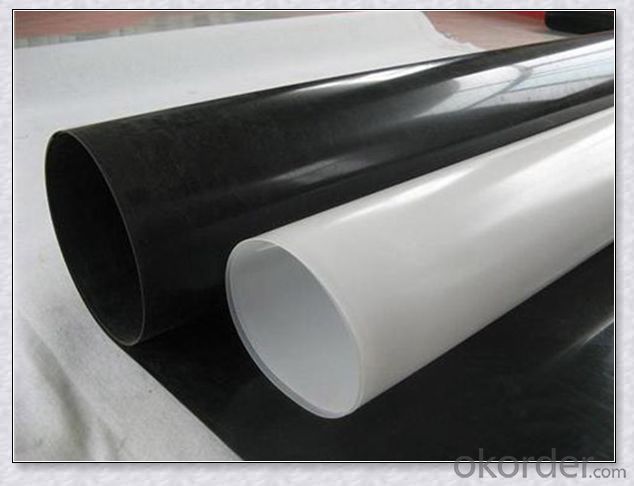

The Wonders of HDPE Geomembranes

HDPE, or high-density polyethylene, is a type of plastic that is highly valued for its strength, durability, and resistance to chemicals, UV radiation, and temperature changes. When used as a geomembrane, it forms an impenetrable layer that prevents leaks and contamination. It's like a superhero cape for your pond, protecting it from all sorts of threats.

Why HDPE is the Go-To Choice

In the world of pond construction, HDPE geomembranes stand out for several reasons. They are incredibly durable, with a lifespan that can extend for decades without significant degradation. This longevity is a major advantage in the oil and gas industry, where long-term stability is key.

Moreover, HDPE is resistant to a wide range of chemicals, which is essential for containing the various substances that can be found in oil and gas ponds. It's like a chemical-resistant shield that keeps everything in check.

Installation: A Seamless Process

The installation of HDPE geomembranes is designed to be as seamless as possible. The material can be easily cut and shaped to fit the contours of the pond, ensuring a perfect fit. Once in place, the geomembrane is sealed using specialized techniques that create a watertight barrier. It's like watching a master artist at work, with every brushstroke perfectly placed.

Environmental Benefits: A Greener Approach

One of the most appealing aspects of HDPE geomembranes is their environmental friendliness. They are made from recyclable materials and can be reused or recycled at the end of their service life. This reduces the environmental footprint of oil and gas operations, aligning with the industry's growing commitment to sustainability.

The Role of HDPE in Pond Life Cycle Management

Throughout the life cycle of an oil and gas pond, HDPE geomembranes play a pivotal role. They provide a stable foundation during construction, protect the pond from leaks and contamination during operation, and can be easily removed and replaced if necessary. It's like having a reliable friend who's always there for you, no matter what.

The Future of HDPE Geomembranes

As the oil and gas industry continues to evolve, the demand for HDPE geomembranes is expected to grow. With advancements in technology and materials, these geomembranes are becoming even more efficient and sustainable. The future looks bright for HDPE, as it remains a cornerstone of pond construction in the oil and gas sector.

Conclusion

In conclusion, HDPE geomembranes are an essential component for ponds in oil and gas operations. Their strength, durability, and environmental benefits make them the top choice for ensuring the safety and efficiency of these critical infrastructures. As we look to the future, the role of HDPE geomembranes is only set to expand, solidifying their place as a key player in the industry.

- Previous:HDPE Geomembranes: The Choice for Ponds in Chemical Plant Pond Lining

- Next:HDPE Geomembranes: The Ideal Material for Ponds in Solar Industry Ponds

-

2024-12-05Geomembrane Liners: A Comprehensive Guide