- Understanding the Role of Geomembrane Liners in Waste Management

- Innovations in Geomembrane Liners for Water Management

- Geomembrane Liners: A Comprehensive Guide

- The Future of Geomembrane Liners in Civil Engineering

- Geomembrane Liners: Enhancing Landfill Stability

Manager:

WhatsApp:+86 177 0135 2670

Tel:+86 177 0135 2670

Email:marketing@okorder.com

Address:3rd Floor, No.2 Building, No.1 Sanlihe Road

HDPE Geomembranes: A Comprehensive Guide for Construction Professionals

hdpe Geomembranes, also known as high-density polyethylene liners, are versatile and robust materials that have become a staple in the construction industry. They are used for a variety of applications, including water containment, waste management, and landscaping. In this guide, we will explore the ins and outs of HDPE geomembranes, from their properties and benefits to installation techniques and maintenance tips.

What Are HDPE Geomembranes?

HDPE geomembranes are made from high-density polyethylene, a type of plastic that is highly resistant to chemicals, UV radiation, and temperature changes. They are known for their durability, flexibility, and ability to create a watertight barrier. This makes them ideal for use in a wide range of construction projects.

Why Choose HDPE Geomembranes?

There are several reasons why construction professionals might choose HDPE geomembranes for their projects. Here are a few of the top benefits:

- Waterproofing: HDPE geomembranes are excellent at preventing water seepage, making them perfect for use in ponds, reservoirs, and other water containment structures.

- Chemical Resistance: They can withstand a wide range of chemicals, which is particularly useful in waste management and industrial applications.

- UV Resistance: HDPE geomembranes are designed to resist damage from ultraviolet rays, ensuring a long lifespan even when exposed to sunlight.

- Flexibility: The material is flexible, allowing it to conform to the contours of the ground and adapt to changes in the terrain.

- Low Maintenance: Once installed, HDPE geomembranes require minimal maintenance, saving time and resources in the long run.

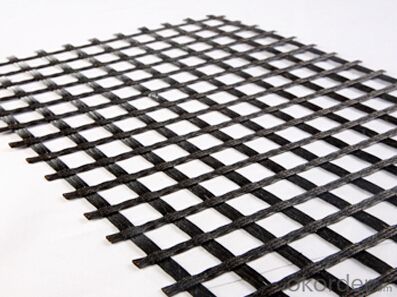

Types of HDPE Geomembranes

Not all HDPE geomembranes are created equal. There are different types available, each with its own set of properties and ideal applications:

- Smooth HDPE Geomembranes: These are the most basic type, offering a smooth surface that is easy to install but may be more prone to slippage.

- Rough HDPE Geomembranes: With a textured surface, these geomembranes provide better traction and are often used in areas where stability is a concern.

- Fusion-Welded HDPE Geomembranes: This type is created by welding the seams together, providing a stronger and more durable seal.

Installation Techniques

Proper installation is crucial to ensure the longevity and effectiveness of HDPE geomembranes. Here are some key steps to follow:

1. Site Preparation: The area where the geomembrane will be installed should be cleared of debris and graded to ensure a smooth, even surface.

2. Handling: Care should be taken when handling the geomembrane to avoid punctures or tears.

3. Seaming: Seams are typically welded using a hot wedge or extrusion process, which creates a strong bond between the layers.

4. Testing: After installation, it's important to test the geomembrane for leaks and ensure that it is properly sealed.

5. Protection: Once the geomembrane is in place, it should be protected from damage during the construction process.

Maintenance and Troubleshooting

While HDPE geomembranes are low maintenance, there are still some steps you can take to keep them in good condition:

- Inspect Regularly: Regular inspections can help identify any potential issues before they become major problems.

- Repair Promptly: If a leak or puncture is detected, it should be repaired as soon as possible to prevent further damage.

- Protect from UV: Although HDPE is UV resistant, it's still a good idea to protect the geomembrane from prolonged exposure to direct sunlight when possible.

- Monitor for Settlement: Over time, the ground beneath the geomembrane may settle, which can cause stress on the material. Monitoring for settlement and addressing it as needed can help maintain the integrity of the geomembrane.

The Future of HDPE Geomembranes

As the construction industry continues to evolve, so too will the use of HDPE geomembranes. New technologies and innovations are likely to improve their performance and expand their applications. Staying informed about these advancements will be key for construction professionals looking to make the most of this versatile material.

In conclusion, HDPE geomembranes are a valuable tool for construction professionals. Their versatility, durability, and low maintenance make them an attractive option for a variety of projects. By understanding their properties, choosing the right type, and following proper installation and maintenance practices, you can ensure that your HDPE geomembrane will serve you well for years to come.

- Previous:The Impact of HDPE Geomembranes on Groundwater Protection

- Next:The Advantages of HDPE Geomembranes in Agriculture

-

2024-12-05Geomembrane Liners: A Comprehensive Guide