- Understanding the Role of Geomembrane Liners in Waste Management

- Innovations in Geomembrane Liners for Water Management

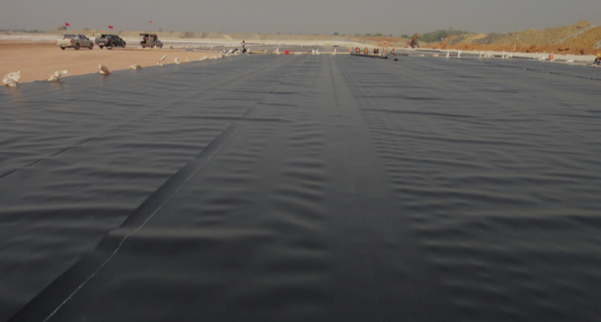

- Geomembrane Liners: A Comprehensive Guide

- The Future of Geomembrane Liners in Civil Engineering

- Geomembrane Liners: Enhancing Landfill Stability

Manager:Alvin Wang

WhatsApp:+62 8983806051

Tel:+86 10-5797-1075

Email:steelwang@okorder.com

Address:3rd Floor, No.2 Building, No.1 Sanlihe Road

At what temperature does HDPE geomembrane become brittle?

High-density polyethylene geomembranes have a high resistance to environmental stresses, flexibility and durability. However, it is subject to temperature-induced variations in its mechanical properties just like any other material. The point at which this type of plastic sheeting becomes fragile due to coldness is a matter of concern when dealing with high-density polyethylene (HDPE) geo-membranes. This discussion will explore into the thermal features of HDPE geo-membrane, identify what makes them brittle as well as give suggestions on how best we can deal with extreme temperatures.

Understanding hdpe Geomembrane

Composition and Characteristics:

High-density polyethylene geomembranes are made from ethylene monomer units which are thermoplastic polymers. They have outstanding strength, chemical resistance and flexibility making them suitable for use in applications where containment is critical such as landfill liners, pond liners or reservoir covers among others. These sheets create an impervious barrier that prevents liquids or gases from seeping through thereby ensuring protection of environment as well as public safety.

Thermal Properties:

Different temperatures make the High Density Polyethene (HDPE) membranes exhibit unique thermal behavior since they possess specific heat capacities associated with their particular structures. When heated above its melting point, thermoplastics become soft but solidify again upon cooling through the glass transition temperature (Tg) up to crystalline melting temperature (Tm).

Factors Influencing Brittleness

Temperature Range:

The range of temperatures within which brittleness sets in varies depending on factors like material composition, processing techniques used during manufacture process and exposure conditions within the outside world. Whilst retaining ductility over wide ranges of coldness normally experienced; however extreme low polar air cold can cause stiffness that eventually leads to cracking or breaking apart.

Cold Embrittlement:

This is a term used to describe loss resistance toughness together with resilience exhibited by some materials when exposed under freezing points. Sub-zero environments subject HDPE geo-membranes to this type of vulnerability where extended periods spent in ice-cold temperatures may affect its mechanical properties significantly either gradually or rapidly as a result sudden changes experienced due fluctuation extreme levels of temperature mainly in cold weather.

Environmental Exposure:

Temperature effects on HDPE geomembrane can be aggravated by environmental factors such as moisture content, ultraviolet radiation and chemical action. Sunlight UV rays may cause surface damage or brittleness especially for those parts not covered by other layers in contact with soil; besides there could also happen moisture penetration through freeze-thaw cycles which eventually lead brittleness development within the matrix.

Strategies for Mitigation

Material Selection:

In order to reduce the brittleness brought about by temperature, it is important that one selects right kind of high density polythene sheeting along with its thickness too. Geomembranes designed using high-quality formulations are more resistant against weathering impacts including those caused extreme variations in temperatures. UV stabilizers antioxidants impact modifiers should therefore be incorporated into formulation process during production stage so as enhance their resistance towards environmental stressors particularly when subjected constant exposure under harsher conditions like higher altitudes or near coastlines where atmospheric conditions tend have greater effect on them.

Regular maintenance and checking are necessary to identify brittleness and temperature-induced degradation signs on HDPE geomembrane installations. Visual inspections, tests to detect leaks and integrity testing are done in order to identify potential problems early enough for them to be repaired or appropriate corrective actions taken which can prevent further damage from occurring hence increasing the lifespan of liners of geomebrane.

Conclusion

In summary, the brittleness point of HDPE Geomembranes is influenced by many factors such as formulation, exposure environment among others. In spite of having good resistance against extreme temperatures; these materials may become brittle due to cold at lower than freezing temperatures. Engineers should therefore have knowledge on thermal behaviour of HDPE Geomembranes so that they can use right methods when installing them in different weather conditions which will guarantee long term performance reliability throughout various climate regions around the world.

- Previous:How strong is HDPE geomembrane compared to steel?

- Next:Does HDPE geomembrane dissolve in water?

-

2024-12-05Geomembrane Liners: A Comprehensive Guide