- Understanding the Role of Geomembrane Liners in Waste Management

- Innovations in Geomembrane Liners for Water Management

- Geomembrane Liners: A Comprehensive Guide

- The Future of Geomembrane Liners in Civil Engineering

- Geomembrane Liners: Enhancing Landfill Stability

Manager:Alvin Wang

WhatsApp:+62 8983806051

Tel:+86 10-5797-1075

Email:steelwang@okorder.com

Address:3rd Floor, No.2 Building, No.1 Sanlihe Road

Can you use geogrid in concrete?

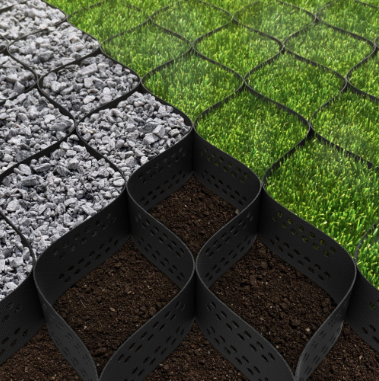

Geogrids have become a very important part of construction, serving as a stabilizer, reinforcement and longevity agent for various structures. Even though their use is usually associated with soil stabilization and erosion control, it can be seen from here that this goes beyond traditional uses. One example of such an application which has gained interest is the usage of geogrids in concrete structures. The aim of this paper is to discuss about the feasibility and advantages involved when different types of geogrids are used in concrete construction including; plastic geogrid, wholesale geogrid, fiberglass geogrid and glassfiber geogrid.

Understanding Geogrids

Geogrinds are made up of polymers or composites like fiberglass attached together forming grid-like materials. They enhance mechanical properties of soils by reinforcing and improving load distribution. Traditionally they have been used in geo-technical engineering practices such as slope stability, retaining wall construction and embankment reinforcement among others. However advancement in construction techniques and material science have extended their range to include applications for construction using concrete.

Plastic Geogrid Concrete

Plastic girds that are made up of high density polyethylene (HDPE) or polypropylene (PP) posses a great tensile strength thus having high durability on them. By doing so they form secondary reinforcements within the concrete thereby distributing loads uniformly throughout it thus reducing cracking. In addition these plastic grids act as uniform force dispersers thereby enhancing the life span and overall performance of these structural elements.

In addition to reinforcing concrete pavements and slabs, plastic geogrid can also be used in overlays and composite structures. This will improve bond strength with the curing matrix hence prevent delamination especially where overlays are thin or other surface treatments exist between them. Furthermore these light constructions make them easy to handle during installation hence most suitable for various projects.

Wholesale Geogrid Concrete

Wholesale geogrids are concrete reinforcement solutions that come in different sizes and configurations. These geogrids are usually purchased in large quantities, hence they can be used for big construction projects since they have low cost. Despite their cheap prices, the products have high performance levels and quality standards that satisfy rigorous engineering requirements.

In concrete use wholesale geogrids provide structural integrity and dimensional stability hence minimizing cracking as well as deformation risks. There is a strong bond between the open-grid design of these grids with the cement matrixes which allow them to share loads effectively while distributing stress. Again, particular project demands can be met by ensuring versatility and adaptability in various building applications through customization of wholesale geogrids.

Fiberglass Geogrid Concrete

Fiberglass geogrid material has high tensile strength, rigidity, resistance to moisture and chemicals. Therefore, these properties make it suitable for use in demanding environments such as concrete structures where durability is very important. It is common to find fiberglass Geotextiles in road pavements, bridge decks and airport runways where there is need to enhance structural performance service life expectancy respectively.

For concrete application processes; fiberglass grid materials are typically added into pavement layers so as to control cracks and improve fatigue endurance capabilities. Despite being flexible enough to withstand dynamic loadings and temperature fluctuations over time into abrasive conditions involving long term operation periods within them this does not affect its integrity design at all. Additionally, fiberglass grids help cut down on the amount of thick slab sections necessary for construction thereby reducing material costs thus quickening project pace.

Glassfiber Geogrid Concrete

The glass fibre geogrids possess a unique combination of strength, pliability and chemical resistance, which makes them suitable for specified use in concrete construction. Manufactured from superior glass fibres, these geogrids exhibit excellent mechanical properties as well as dimensional stability that allows them to provide predictable performance under harsh environmental conditions. Overlaying is the most common application of glassfibre geogrids in bridge decks and industrial flooring systems to enhance structural integrity and durability.

Inclusion of Glass Fiber Geogrids in Concrete

Integration of this material into a concrete mix provides glass fiber reinforcement such as enhanced crack control with minimized maintenance needs and life extension. The corrosion resistant nature make it highly applicable for marine applications along coastal regions where there are salt water and aggressive chemicals. In addition, the bond between them is very strong on concrete matrices of fiber-glass and thus they perform optimally over wide range of constructions.

Conclusion

Geogrid incorporation in cement works out fine for several reasons such as; improved structural integrity, increased service life besides diminished upkeep expenditures. Each kind has its own distinctive characteristics: plastic geotextile woven retina wholesale grid, fiberglass grid or even utilizing the method similar to the one mentioned earlier using the substance known like Glassfiber Grid Composite- GFRCG . By considering these factors during design, engineers can optimize performance and durability thereby ensuring sustainable infrastructure for future generations.”

-

2024-06-12Asphalt fiberglass geogrid construction plan

-

2024-06-04Asphalt fiberglass geogrid construction plan

-

2024-05-21What is the disadvantage of geogrid?

-

2024-05-21What is the lifespan of geogrid?

-

2024-05-21What are the 3 main uses of a geotextile?