- Understanding the Role of Geomembrane Liners in Waste Management

- Innovations in Geomembrane Liners for Water Management

- Geomembrane Liners: A Comprehensive Guide

- The Future of Geomembrane Liners in Civil Engineering

- Geomembrane Liners: Enhancing Landfill Stability

Manager:

WhatsApp:+86 177 0135 2670

Tel:+86 177 0135 2670

Email:marketing@okorder.com

Address:3rd Floor, No.2 Building, No.1 Sanlihe Road

Decoding HDPE Geomembrane Liner Manufacturers: Venturing Into the Meaning of Innovation and Sustainability

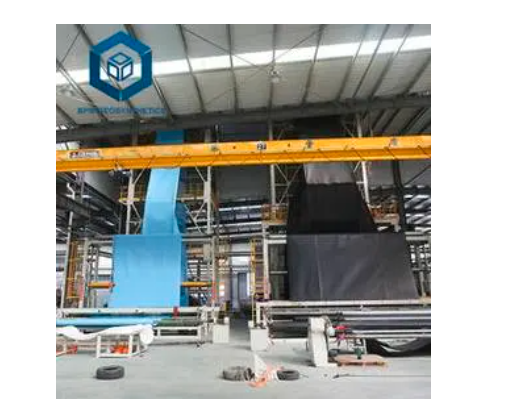

In this expansive construction environment and environmental protection industry, a silent hero has risen up in the name of hdpe Geomembrane liner. These high density polyethylene liners are used for numerous containment projects and security purposes ranging from landfills, water reservoirs, to mining operations or fish farming enterprises. The demand for these products therefore makes it necessary to consider hdpe geomembrane liner manufacturers. This article is concerned with these manufacturers’ contribution, innovations and their impact on sustainable engineering practices.

A Shield that is HDPE Geomembrane

The presence of an HDPE geomembrane liner at the core of many environmental and containment projects defines versatility as a durable barrier that is virtually impenetrable. They are made from high-density polyethylene polymers which have been engineered to provide strength, flexibility as well as chemical resistance properties. Manufactured in long rolls, they are then installed on site to act either as a barrier layer for containment or as preventive measure against migration of contaminants. Among other crucial features, HDPE demonstrates good UV resistance property, excellent chemical resistant characteristic including stability against crack due to environmental stress.

Unraveling the World of HDPE Geomembrane Liner Manufacturers: A Deep Dive into Innovation and Sustainability

Titan Environmental: Where Quality Begins

In relation to the market for HDPE geomembrane liners Titan Environmental has built its reputation synonymous with quality and reliability in terms of durability. On account of its ability to withstand higher temperatures combined with its resistance to wide range solvents; there are preferred choices used for lining projects such as their High Density Poly Ethylene (HDPE) Geo Membrane Liners by them. Apart from being welded using hot wedge welders coupled with extrusion welders in field conditions thereby ensuring factory quality seams said to be stronger than the sheet itself exemplifies Titan’s commitment to quality and detail. As such, any project that necessitates the highest level of chemical and ultraviolet resistance can find a reliable source in Titan environmental.

Revealing Geomembrane Murah

Geomembrane Murah is a user-friendly resource for those who need comprehensive information on HDPE geomembrane liners including how they should be used, what to pay attention to when selecting them and how one can install them correctly. Among other factors important in the selection of HDPE geomembrane include thickness, texture, and certified properties. It also underscores the significance of correct installation which includes site preparation, deployment, field seaming, anchoring and quality assurance. This resource provides valuable information on understanding the intricacies involved with HDPE geomembranes as well as tips on successful use.

AGRU America: Pioneers in Innovation

AGRU America is a leading North American manufacturer of structured and embossed geomembranes. Their manufacturing process using flat die cast extrusion enables production of the most consistently smooth or textured geomembranes owing to their patent rights. AGRU employs high-density polyethylene (HDPE) and linear low density polyethylene (LLDPE) in its liner systems thus making sure they have first-rate containment properties coupled with stability against chemicals attack. Some examples are Super Gripnet® Liner, MicroSpike® Liner or AGRU Drain Liner®, each tailored specifically for certain project specifications besides providing advanced leak detection systems together with drainage solutions.

YF Geosynthetics: Diverse Applications and Benefits

YF Geosynthetics specializes in manufacturing HDPE geomembranes, Geotextiles as well as geosynthetic clay liners among others. They design products that serve many purposes such as road work or environmental safety measures. For example, they stress upon corrosion resistant nature combined with long life span characteristics of their geogrids that are enhanced by various additives against aging and oxidation. This commitment to performance and longevity means YF Geosynthetics offers top quality geosynthetic materials for use in any project area where such are required.

Key Factors to Consider in the Selection of HDPE Geomembrane

Several factors count when opting for HDPE geomembrane; this guarantees that they match the specific containment applications. Among these are liner thickness, which is between 30 and 200 mils, with thicker liners providing increase puncture resistance. The alternative between sheet and roll goods depends on size of project with rolls accommodating larger liners for less field seams. An important consideration is also texture where smooth geomembranes are good for pond and lagoon liners while steep-lined slopes require textured materials.

Best Practices in Installation

Getting a durable and water-impermeable geomembrane liner requires proper installation. Key steps include site preparation such as smoothing the soil surface until it is compacted and cleared of any debris; laying down the liner without much wrinkling onto it, fusing by use of thermal fusion or extrusion welding techniques; securing against wind uplift or sliding using anchors, as well as additional protective layers against punctures and weathering. It should be considered testing and quality assurance rigorously to ensure there are no holes, wrinkles or gaps in the liner.

Uses of HDPE Geomembrane Liners

HDPE geomembranes have numerous uses where durable containment and protection are necessary. Some of them include:

Landfill Liners: Most frequently, HDPE geomembranes are used as bottom linings for municipal solid waste landfills. According to EPA regulations, composite liners consist of flexible membrane over two feet compacted clay. Chemical resistance and low permeability qualities make HDPE geomembranes an ideal flexible layer.

Mining Applications: Mines need HDPE geomembranes for various containment purposes like heap leach pads, tailings ponds or waste rock facilities among others. These prevent leaching solutions from escaping thereby enhancing mineral extraction efficiency with minimum environmental risks.

Water Resources Management: In water projects such as reservoirs, canals or ponds, geomembrane liner made from HDPE gives a watertight barrier that can maintain water resources, minimize water losses and overall improved water management.

Aquaculture and Fish Farming: For aquaculture applications, the HDPE geomembrane liner is used to create pond liners that prevent water seepage, maintain proper water levels, and create an ideal environment for fish and shrimp farming.

The Future of HDPE Geomembrane Liner Manufacturers

The demand for these liners keeps rising as industries begin to realize how versatile and reliable they are in environmental containment. Industry leaders like Titan Environmental, Geomembrane Murah, AGRU America, YF Geosynthetics are paving way for year’s of innovation in this sector by providing innovative solutions as well as benchmarking high quality products. With projects growing more intricate and regulations getting tighter, the role played by HDPE geomembranes in safeguarding the environment and ensuring safety in containment systems will only become more crucial.

In summary, the world of hdpe geomembrane liner manufacturers demonstrates human resourcefulness and determination to find sustainable answers. The makers are not mere suppliers but also partners who pursue environmentally friendly ways. Their dedication to customer satisfaction, quality improvement through innovation has made them industry players; therefore there is every reason to say that future containment solutions will be just as secure as their linings.

Environmental protection is the future that HDPE geomembrane liner manufacturers are shaping one project at a time. In our exploration and innovation journey, these liners will be central to environmental conservation, as we strive to manage responsibly our resources. The voyage of an HDPE geomembrane liner is not only about confinement but also about our consensual dedication towards a consistent eco-future.

- Previous:Explaining the Dynamics of Geomembrane Sheet Prices in Pakistan: An In-Depth Dive

- Next:Reinforced Polypropylene Geomembrane: Our Environment’s Shield