- Understanding the Role of Geomembrane Liners in Waste Management

- Innovations in Geomembrane Liners for Water Management

- Geomembrane Liners: A Comprehensive Guide

- The Future of Geomembrane Liners in Civil Engineering

- Geomembrane Liners: Enhancing Landfill Stability

Manager:Alvin Wang

WhatsApp:+62 8983806051

Tel:+86 10-5797-1075

Email:steelwang@okorder.com

Address:3rd Floor, No.2 Building, No.1 Sanlihe Road

How can you tell the quality of bentonite?

It is a versatile clay mineral used in various industries, among them construction, where it is in form of bentonite blankets. In civil engineering, especially when soil composition poses a risk of water infiltration; these blankets are commonly used for waterproofing. They work as barriers that help to keep water out of structures like basements, tunnels and retaining walls. Not all bentonite blankets are created equal though, as the quality of the bentonite employed contributes significantly to their effectiveness. So how do you tell if the bentonite on site is good enough? Let us look at some key indicators.

1. Purity of Bentonite

The purity of the material is a primary determinant of its quality. High-quality bentonite blankets are made from virgin clay that contains no impurities such as sand or silt and other minerals. Presence of these impurities may therefore compromise the integrity and efficiency in making this blanket act as a barrier to water penetration through it. The idea behind testing for purity by many manufacturers is to ensure that they have met with specifications required for their products.

2. Swelling Capacity

One outstanding property for which bentonites are famous is their ability to swell upon absorbing water . This behavior makes bentonites excellent materials for waterproofing applications . In addition , higher swelling capacity implies better sealing ability against any cracks or openings in soil that would otherwise lead to water seepage through it . While determining overall quality, attention should be given to swelling capacity which is usually expressed as swell index . A higher number indicates superior-quality material providing improved protection against leakage.

3. Permeability

Permeability refers to how well fluids (liquids/gases) pass through material substance (U.S.Bureau of Reclamation 1999). For purposes of better waterproofing performance low permeability levels are preferred when designing and using Bentonite blankets. High-end Bentonite has low permeability, hence does not allow water to move across the blanket entailing moisture barrier for structures. Permeability tests are usually done in order to determine the quality of bentonite and ascertain that it is fit for purpose when it is used in waterproofing.

4. Particle Size Distribution

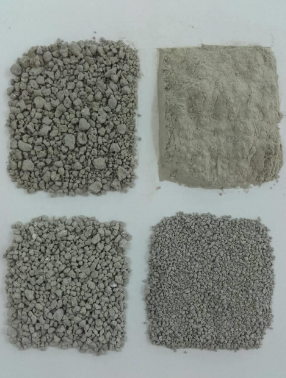

Particle size distribution of bentonite clay has a great impact on its performance as bentonite blankets. Ideally, uniform particle sizes should be contained within the clay to enable better compaction and sealing capabilities. In case there is variation in particle sizes then gaps which reduce efficiency may occur within the blanket hence making it less effective for purposes of preventing moisture intrusion into buildings. To ensure such reliable performance under diverse soil conditions, reputable manufacturers of high-grade bentonite blankets control their clays' particle size distributions.

5. Chemical Composition

The swelling capacity and permeability are among other properties that depend on the chemical composition of bentonites (Ratnaweera et al., 2010). Generally, montmorillonite is found mainly in bentonites which falls into smectite family having expansive properties (Coutney 1968) . The presence of minerals like quartz or feldspar can affect its performance in waterproofing applications . High-quality Bentonite blankets consist of Bentonites with well-balanced chemical compositions thus enhancing waterproofing abilities and long service life.

6. Compatibility with Soil

1. Bentonite blankets are successful in waterproofing applications if they can be used in congruence with the soil wherein it is intended to be used. This means that the blanket should be able to bond effectively with the soil, forming an impermeable barrier against water penetration through it. The compatibility of bentonite with the surrounding soil may depend on factors like soil pH, texture and mineral content of the soil. In order to ensure that good quality bentonite blankets maintain their compatibility with different soils and hence can be relied upon for waterproofing under different environmental conditions, they have been engineered so.

7. Manufacturing Process

The manufacturing process plays a significant role in determining whether or not bentonite blankets will waterproof properly. Right from mining and processing of raw bentonite clay up to fabrication of these blankets, each step has to conform to strict standards of quality control so as to meet desired specifications by end product manufacturers. To obtain bentonite blankets which are consistent in terms of quality and performance, manufacturers employ advanced techniques and machinery. The manufacturing process involves batch testing and quality audits as part of quality assurance measures aimed at identifying any deviations from particular standards.

Conclusion

In conclusion, bentonite qualities determine how efficient they are when it comes to using them as waterproofing material in form of bentonite blankets. This calls for consideration of characteristics such as purity, swelling capacity, permeability, particle size distribution, chemical composition; compatibility with soil among other things alongside manufacturing procedure so that stakeholders will know how good or bad is this stuff when building structures; thus helping them to make informed decisions about its application in construction projects... Moreover investment into high-quality Bentonite Blankets guarantees first-rate water proofing capability but also contributes towards longevity and stability of buildings.”

- Previous:How many types of bentonite are there?

- Next:Is bentonite a cement?

-

2024-05-15How long does bentonite waterproofing last?

-

2024-05-15What is bentonite used for?

-

2024-05-15What happens when bentonite gets wet?

-

2024-05-15Does bentonite go bad?