- Understanding the Role of Geomembrane Liners in Waste Management

- Innovations in Geomembrane Liners for Water Management

- Geomembrane Liners: A Comprehensive Guide

- The Future of Geomembrane Liners in Civil Engineering

- Geomembrane Liners: Enhancing Landfill Stability

Manager:Alvin Wang

WhatsApp:+62 8983806051

Tel:+86 10-5797-1075

Email:steelwang@okorder.com

Address:3rd Floor, No.2 Building, No.1 Sanlihe Road

How does HDPE geomembrane fail?

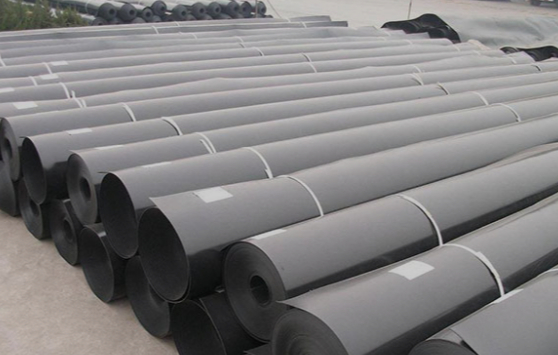

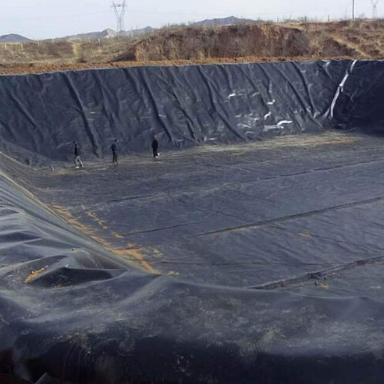

High-density polyethylene (HDPE) geomembranes are commonly used in many civil engineering and environmental applications due to their durability, ductility and impermeability. Be it for landfill lining or pond capping or even irrigation canal covers and wastewater treatment plants, hdpe Geomembranes have multifunctionalities that prevent liquids as well as gases from passing through them thus ensuring environmental protection. However, despite the several merits of HDPE geomembrane materials, they can fail under certain circumstances. What are some ways in which HDPE geomembrane can fail? Below are explored.

Understanding HDPE Geomembranes

However, let’s first look at the properties and characteristics of these membranes before discussing failures. On the other hand high density polyethylene Geomembrane is a synthetic liner made from high density polyethylene resin. This thermoplastic material is corrosion resistant with great mechanical strength and flexibility that makes it suitable for various containment applications.

Common Failure Modes

The failure modes for HDPE geomembranes include but not limited to; environmental conditions, installation practices, material defects and aging among others. Puncture and tear are examples of most common types of failures that affect HDPE geomembranes. Sharp objects such as heavy machinery or abrasive materials can puncture or tear through the liner thereby compromising its integrity resulting in leakage or seepage occurring within it. The poor installation practices such as poor surface preparation or improper handling may also increase the risks associated with puncture and tear failure.

Seanm Failure

Seanm failure occurs when the welded/bonded seams on an HPDE geombrane do not offer enough strength/durability to make them water tightness.Inadequate welding techniques may lead to this issue with things like insufficient seam overlap material contamination causing leaks/separations.The problem is most critical when reliable containment must be ensured by a geomebrane such as in landfills or wastewater treatment facilities.

Chemical Degradation

Chemical degradation refers to the corrosion of HDPE geomembranes by highly corrosive chemicals or other aggressive substances. Acids, alkalis, solvents and hydrocarbons are some examples of chemicals that weaken the molecular structure of a geomebrane and can therefore cause it to degenerate over time. Chemical degradation may appear as discoloration, embrittlement or loss of mechanical properties; eventually leading to failure of the geomebrane liner.

Environmental Stress Cracking

Environmental stress cracking is a phenomenon experienced by HDPE geomembrane where it cracks as a result of environmental stressors such as temperature changes, exposure to UV radiation and oxidative agents. These have been found to cause cleavage in the material chains weakening their mechanical properties hence causing them to crack/become brittle. This is one common mode among many geomembrane failures that are exposed to open air like ponds and reservoirs.

Installation Damage

HDPE geomebranes can be damaged during handling, transportation or installation processes. Rough handling, improper storage conditions or equipment accidents can lead to physical damage on the geomebrane such creases/folds/tears etcetera. Such damages which occur during installation compromise the integrity of a Geomembrane liner thus making its chances of failure higher with time.

Preventive Measures

Some preventative measures for reducing HDPE geomebrane failure risk include:

1.Proper Design and Engineering

Those designing HDPE Geomembrane Liners must take into account various factors so as to ensure they do not fail prematurely.Aspects such as environmental conditions, site attributes expected loadings and chemical exposures should be evaluated carefully in order develop a geomebraneous system capable of resisting possible stressors while ensuring containment certainty.

2.Quality Assurance

5. Materials of Construction

The materials to be used for constructing the HDPE geomembrane should be carefully selected so as ensure its integrity and high performance. The selection process should consider factors such as environmental exposure, type of liquid being contained, and installation conditions.

3. Proper Installation Practices

The effectiveness and life cycle of HDPE geomembrane liners heavily depends on proper installation practices. This means that appropriate seam overlap, correct welding techniques, adequate surface preparation and quality control measures are necessary to achieve watertight seals and seam integrity. In order to minimize installations issues it is better to have it done by professionals who have been trained and have experience in the field.

4. Chemical Compatibility

In summary, it is important to use HDPE geomembrane liner material that is compatible with the chemicals available at a given containment site in order to avoid chemical degradation or failure. To verify whether or not a certain geosynthetic material is appropriate for a specific application and chemical environment; compatibilities must be tested.

Conclusion

HDPE geomembranes may fail due to various reasons including punctures/tears, seam failures, chemical attacks, environmental stress cracking (ESC), or mechanical damages during installation process. To prevent this from happening engineers should know the modes of failure that can happen in their respective designs and implement preventive actions which will help them safeguard against risks leading to long term serviceability of these systems for containment applications.

-

2024-12-05Geomembrane Liners: A Comprehensive Guide