- Understanding the Role of Geomembrane Liners in Waste Management

- Innovations in Geomembrane Liners for Water Management

- Geomembrane Liners: A Comprehensive Guide

- The Future of Geomembrane Liners in Civil Engineering

- Geomembrane Liners: Enhancing Landfill Stability

Manager:

WhatsApp:+86 177 0135 2670

Tel:+86 177 0135 2670

Email:marketing@okorder.com

Address:3rd Floor, No.2 Building, No.1 Sanlihe Road

Modern Engineering Evolution and Impacts of PE Geomembranes

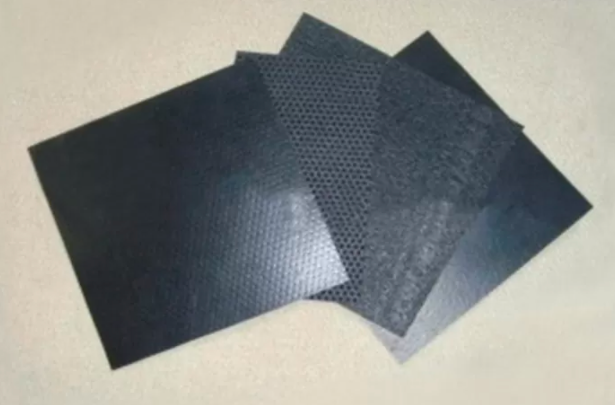

In modern engineering applications, polyethylene (PE) geomembranes have become a mainstay, particularly in the world of geosynthetics due to their versatility and strength. These sheets, which are extremely thin and flexible, are made from linear low-density polyethylene (LLDPE) or high density polyethylene (HDPE), and are known for being impervious, long-lasting, and easy to install. In this article we will examine the developments in PE geomembranes; these include its growth as well as material properties it has achieved with time.

The Emergence of PE Geomembranes

The history of PE geomembranes started in 1970s when HDPE resins were first acknowledged as useful for making resistant barriers that are also durable. Subsequently MDPE materials became more commonly used instead of HDPE because they had better resistance to stress-cracking effect. Use of LLDPE with comonomers like 1-Hexene (C6) provided a more flexible alternative with slightly lower chemical resistance but easier weldability. It was not until bimodal polymerization technology surfaced in 1990’s that there could be production at low cost LLDPE and MDPE resins that possess better processability and mechanical properties.

Material Developments and Innovations

The progress experienced by PE materials has been truly amazing. The beginning of metallocene catalysts early in the 2000s paved way for production of ultra-pure consistent PE resins having excellent mechanical and sealing features. Metallocene LLDPE (mLLDPE) with C6 and 1-Octene (C8) comonomers ushered in new generation geomembranes having far improved mechanical characteristics than those made using other polymers. Modern advances have focused upon bimodal LDPE & HDPE types having advantageously better processability, weldability and mechanical properties.

The Role of PE Geomembranes in Geosynthetic Applications

In geosynthetics, PE geomembranes have found their place in various applications from liners in landfills to canal linings, and reservoir covers. Their ability to make a barrier that does not let any kind of fluid pass through them makes them also very useful for containment of fluids as well as isolating fluids from the ground. The environmental demands and performance expectations have driven the need for higher levels of performance from these geomembranes, leading to continuous material innovation.

Stress Cracking Resistance and Material Reliability

PE geomembranes are highly susceptible to stress cracking which is brittle failure associated with highly crystalline microstructure. Such issue has been addressed by developing new materials that have better stress crack resistance such as PERT-based hdpe Geomembranes with three times greater stress crack resistance than standard HDPE geomembranes. This advancement is crucial for ensuring the longevity and reliability of geomembrane applications in the field.

The Future of PE Geomembranes in Hydropower

The fact that they (PE geomembranes) can be used for hydropower generation indicates how adaptable they are since this is an industry that demands high effectiveness. They act as impervious layering in hydraulic canals, reservoirs, dams among others water pressure channels thus supporting structural integrity or efficiency of these systems. As the hydropower sector evolves, the need for maintenance, rehabilitation, and extension of existing plants becomes more critical therefore making PE geomembranes an important technology for sustainable hydropower development.

Personal Reflection on Polyethylene (PE) Geomembranes

By delving into the nitty-gritty of PE geomembranes and their use, it becomes almost impossible to neglect the genius manifest in these materials. They are not just plastic layers; they’ve been researched upon for years on end and invented to meet the stringent requirements of engineering works. To see these more than half a century old structures being integrated successfully into projects with the knowledge that they can last long time is very gratifying.

Conclusion: The Unfolding Story about PE Geomembranes

The tale of polyethylene (PE) geomembranes is an ongoing one, as we see vast new discoveries and technological innovations taking shape all around us. It’s impact on geosynthetic disciplines is irrefutable while its potentiality for future uses remains immense. From deep within garbage dumps to towering across dams, little known PE geomembranes play their roles quietly but sure with no letdowns whatsoever. Looking ahead, there is no doubt that this multifaceted material will continue being part and parcel of our engineering pursuits as reflected by human genius in sustainability.

In conclusion, this story traces the remarkable journey from inception to its present status as one of the most vital constituents in different industries, which underscores inventiveness and adaptability of mankind over time. As we press forward into unknown realms, PE geomembranes must now assume a greater significance in our engineering ventures signaling our capacity for making things happen, defending them when threatened and succeeding against all odds.

- Previous:Stitching the Earth's Fabric: A Journey Through the World of Geomembrane Welding Machines

- Next:The Rise and Fall of Bituminous Geomembranes (BGMs) in the World of Geosynthetics