- Understanding the Role of Geomembrane Liners in Waste Management

- Innovations in Geomembrane Liners for Water Management

- Geomembrane Liners: A Comprehensive Guide

- The Future of Geomembrane Liners in Civil Engineering

- Geomembrane Liners: Enhancing Landfill Stability

Manager:

WhatsApp:+86 177 0135 2670

Tel:+86 177 0135 2670

Email:marketing@okorder.com

Address:3rd Floor, No.2 Building, No.1 Sanlihe Road

The Geomembranes Welder: Mastering the Art of Environmental Protection

The geomembrane welder in the large picture frame of geotechnical engineering is a silent maestro who orchestrates the union between these materials with precision and care. This paper pays homage to the art of geomembrane welding, a trade that requires an understanding of both technical skills and knowledge about different materials and their use.

The Symphony of Welding: Understanding the Process

Welding geomembranes can sometimes be represented as composing a symphony, where each note or in this case every parameter must be perfectly tuned to create harmonious output. The geomembrane welder knows what seam strength means, which is as tough as the material itself to make an impervious barrier for successful projects.

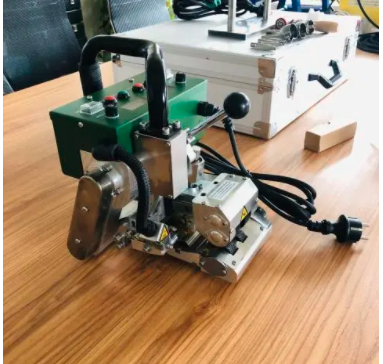

Tools for Trade: Techniques and Equipment Used in Welding

Just like brushes are differentiated by painters while painting, so have to choose from various welding techniques and equipment that suit unique requirements of any given project just like a geomembrane welder. The procedures are accompanied by sets of tools and best practices that have to be mastered by any person using them like hot-air welding or extrusion welding.

Hot-Air Welding: In this case, it’s a gentle wind blowing through these surfaces with hot air streams. So then she moves closer in order to weld them together allowing bond stronger than its fabric once softening those faces with heat.

Extrusion Welding: This is more like when sculptor uses his experienced hands softly molding clay whereby heating up welding rod then forcing into line leads finally connects all parts firmly thus making them durable.

Chemical Welding: There exists one way out—subtle dance performed through dissolving agent on PVC or Urethane based geo-membranes. In such cases sheets get pressed against each other as evaporation leaves permanent bonds behind after couple seconds since started dancing he calls it “welding.”

Wedge-Welding: This is where two pieces of wood are joined by a carpenter with one accurate joint; in a similar manner, through wedge-welding, sheets are heated at the point between them using a handheld machine which is pressed together to generate a straight long weld.

The Conductor's Baton: Factors Influencing Weld Quality

A quality weld is the harmony that geomembrane welders want to achieve. Finally, factors such as type of geomembranes, welding method and environmental conditions play vital roles in this performance.

The Stage Directions: Best Practices for Welding

There’s an indication on how we can make our geomembrane welding better. A director does this by observing all parameters used during welding like heat/energy, speed and pressure vigilantly.

The Dress Rehearsal: Field Welding Considerations

Just like actors preparing for different performances under diverse circumstances, when it comes to fieldwork activities these people take note about ambient temperatures and similarity of materials the same way they do.

The Critique: Testing and Quality Assurance

It’s about taking her work into the microscope after everything has been done in order to test the quality of her work. The strength of welds may be evaluated by destructive tests such as peel testing or shear testing while seam integrity at the scene can be tested for leaks.

The Encore: The Development of Welding Equipment

As one project ends, the geomembrane welder anticipates the next with a full realization that welding equipment and methods are evolving.

Conclusion: A Craft of Passion and Precision

Geomembrane welding is an art that requires passion and precision; a process in which the welder’s mastery of materials’ behavior in certain environments combine to build up a protective barrier. It is a craft that demands more than technical skills; it calls for an appreciation of material subtleties and situational contexts. In this regard, with geotechnical engineering increasingly pushing limits, the geomembrane welder is still indispensable in relation to our infrastructure development since his or her contribution will ensure that seams are not only strong but also bear witness to welding expertise and hard work.

- Previous:The Enchanting Realm of Geomembranes: Decoding the Mysteries of Geomembrana Precio.

- Next:Que es Geomembrana: The Unsung Heroes of Modern Engineering

-

2024-12-05Geomembrane Liners: A Comprehensive Guide