- Understanding the Role of Geomembrane Liners in Waste Management

- Innovations in Geomembrane Liners for Water Management

- Geomembrane Liners: A Comprehensive Guide

- The Future of Geomembrane Liners in Civil Engineering

- Geomembrane Liners: Enhancing Landfill Stability

Manager:Alvin Wang

WhatsApp:+62 8983806051

Tel:+86 10-5797-1075

Email:steelwang@okorder.com

Address:3rd Floor, No.2 Building, No.1 Sanlihe Road

What are the problems with HDPE geomembrane?

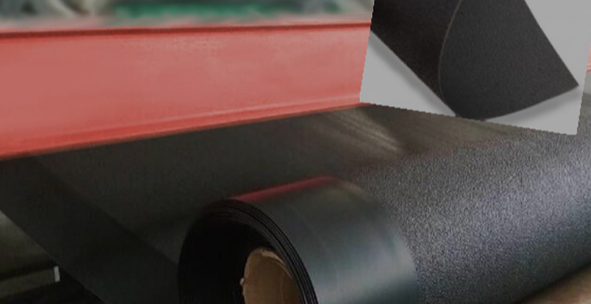

For years now, hdpe Geomembrane has remained a flexible and enduring solution for many kinds of containment applications such as landfills to water storage reservoirs. It is resistant to chemical attack, punctures, and UV radiation thus making it commonly used among engineers and ecologists. Nonetheless, like any other engineering material, there are also challenges that come along with HDPE geomembrane. This paper deals with some of the major problems associated with HDPE geomembrane and how they can be resolved.

1. Seam Integrity

Seam integrity is one of the most important concerns in relation to installing HDPE geomembranes. Seams are areas where two sheets of geomembrane are joined during installation. If not done properly, seams can be weak points that may leak or fail in due course. Poor fusion, incomplete welding or surface preparation issues may lead to seam failure.

2. Chemical Compatibility

Despite being generally highly resistant to chemicals, certain substances might still affect the long-term integrity of HDPE geomembranes because they react with and eventually destroy the materials over time. The result could be degradation by aggressive chemicals such as acids, solvents and hydrocarbons leading to loss of their mechanical strength properties. At higher concentrations in particular chemicals contact on this kind of plastic film can cause it to swell up, soften or harden hence increasing chances of its failure.

3. Environmental Stress Cracking

Environmental stress cracking represents another significant issue that affects performance of HDPE geomembranes. The combined effect of tensile stress levels acting on the liner’s surfaces under sun light exposure as well as immersion into solutions carries severe consequences for them since they may develop micro-cracks all through their structure resulting in potential leakage sites being formed within them. ESC particularly prevails in exposed locations like open landfill areas or wastewater treatment plants.

4. UV Degradation

Even though it is naturally resistant to UV, HDPE geomembrane is still affected by this element over long periods of time. The surface could become brittle and break with exposure to prolonged sunlight resulting in cracking, crazing and loss of mechanical strength in the material. Although UV stabilizers are usually added into the HDPE resin formulations to counteract the UV effect on them, their effectiveness can be reduced after some time especially where there is high UV exposure.

5. Installation Challenges

Proper installation is crucial for the long-term performance and efficiency of HDPE geomembranes. However, this process may prove difficult especially in complex geometries or challenging site conditions. Problems like poor surface preparation, incorrect seam welding or an uneven substrate can undermine system integrity and increase the risk of leaks. Additionally, difficulties associated with installation can be made worse by inexperienced installers coupled with insufficient quality control measures leading to expensive repairs or even replacements.

6. Differential Settlement

Inequalities in how the ground under a geomembrane liner settles may have serious implications for installations involving HDPE geomembrane liners. When soil compaction varies; moisture content changes as well as loading differs across certain areas then differential settlement may result which would lead to stress concentrations as well as damage on the liner’s material. It is important that a proper site work including soil stabilization and compaction be done before laying down any geosynthetic liners thus reducing settlement related problems.

7. Thermal Expansion and Contraction

The installation of HDPE geomembranes is often as problematic as thermal expansion and contraction, especially in areas experiencing considerable temperature variations. Whenever temperatures change, the geomembrane material stretches and shrinks stressing seams, anchorages, and interfacing with subgrades. Lacking ample provisions for thermally induced movements; this can result into seam failures, creases and ballooning of the liner. Adequate consideration during design such as incorporation of expansion joint or flexible anchorage system(s) would enable the membrane accommodate thermal movements as well as minimize the extent of damage.

8 Conclusion

Despite its numerous advantages when used as a containment solution material, HDPE geomembrane has some potential issues that need to be recognized and addressed. Starting from the integrity of seams to chemical compatibility concerns to environmental degradation; it requires careful planning, execution and maintenance over time to ensure long-term performance and effectiveness of HDPE geomembranes. By understanding these challenges and implementing appropriate mitigation strategies, engineers and environmentalists can harness the full potential of HDPE geomembrane while minimizing risks and maximizing durability.

-

2024-12-05Geomembrane Liners: A Comprehensive Guide