- Understanding the Role of Geomembrane Liners in Waste Management

- Innovations in Geomembrane Liners for Water Management

- Geomembrane Liners: A Comprehensive Guide

- The Future of Geomembrane Liners in Civil Engineering

- Geomembrane Liners: Enhancing Landfill Stability

Manager:Alvin Wang

WhatsApp:+62 8983806051

Tel:+86 10-5797-1075

Email:steelwang@okorder.com

Address:3rd Floor, No.2 Building, No.1 Sanlihe Road

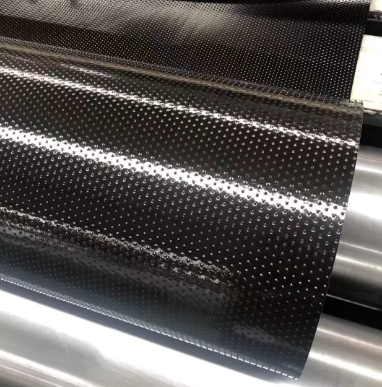

What is the difference between HDPE and LLDPE geomembrane?

Geomembranes are an important part of construction and environmental projects as they provide containment solutions for various applications. In these projects, two common types of geomembranes are High-Density Polyethylene (HDPE) and Linear Low Density Polyethylene (LLDPE). Despite having a number of similar properties, hdpe Geomembranes differ from LLDPE in some aspects. This article examines such differences, their respective characteristics and uses.

Introduction to HDPE and LLDPE Geomembranes

Synthetic liners made from polyethylene polymers which belong to a versatile group of thermoplastics widely employed in geomembrane applications are referred to as HDPE and LLDPE geomembranes. For different civil engineering works, environment-related problems, geotechnical issues they were developed as containment or fluid barrier solutions. Although the raw materials used to make HDPE and LLDPE geomembranes have a common chemical composition; however, the resultant products have distinct characteristics thus performances.

Composition and Molecular Structure

The difference between HDPE and LLDPE geomembrane is in their molecular structure ,and polymer chain arrangement:

- HDPE Geomembrane: – high-density polyethene(abbreviation: HDGE), which is one type of thermoplastic polymer with high molecular density level coupled with chain branching. The linear molecule structure is made up tightly packed molecules polyethylene molecules that have very little branching. Due to the rationality behind this molecular organization, it has become possible for them to be highly resistant against mechanical strength along with great stiffness.

- LLD PE Geomembrane: – on other hand stands liner low density polyethene(abbreviation: LLDP) whose type has less degree of molecular density with many side chains more than that of HDGE . These mats are made out of linear polyethylene molecules which have few short branches or side chains attached to the main polymer chain. The flexibility of LLDPE geomembrane is enhanced by this molecular structure compared to HDPE as they are characterized with a number of elongation properties at break.

Physical and Mechanical Properties

Due to their distinct molecular structures, HDPE and LLDPE geomembranes exhibit varied physical and mechanical properties:

- Flexibility: – due to its lower degree of crystallinity as well increased chain branching; LLD PE geomembrane is more flexible and ductile than HDPE . This feature allows them to adapt to irregular surfaces, withstand ground movements and change without compromising their integrity. On the other hand, HDGE is less flexible than LLD PE, but presents superior stiffness as well as dimensional stability within it.

- Tensile Strength: – when compared with LDG PE geomembranes, HDG PE geomembranes usually exhibits higher tensile strength along tear resistance due to the fact that they have dense molecular structure and linear chain arrangement. They can withstand high loadings, stresses puncture forces without tearing or rupturing making them ideal for applications that involve robust mechanical properties.

- Elongation at Break: – this means that an LLD ME geomembrane stretchs more upto before it breaks in comparison with HDG ME geombrane which has a low elongation at break. This property makes it more resistant to elongation deformation and cracking under tensile stress especially in scenarios where there is dynamic loading or shifting of earth.

- Impact Resistance: – thanks to the energy absorption capacity being small given its greater flexibility of movement in relation to HDG PEME; LLDP EM has better impact resistivity also perforation resistance . Such types can be used under sharp things’ impacts on them therefore should be employed for heavy loads including dynamic ones which require improved impact resistance.

Applications and Suitability

However , whether any representative design requires either type relies on the specific project demands and performance criteria.

- HDPE Geomembrane Applications: HDPE geomembranes are ideal for applications that necessitate strong tensile strength, chemical resistance and dimensional stability. They are commonly used in landfill liners, pond liners, wastewater treatment plants, mining projects among other industrial containment systems where reliable mechanical qualities and long-term durability are obligatory.

- LLDPE Geomembrane Applications: LLDPE geomembranes are preferred where flexibility, elongation properties and impact resistance are key. They are often used as pond liners, secondary containment systems, agricultural ponds or decorative ponds which must fit to irregular surfaces and not get knocked out of shape easily.

Conclusion

To sum up, HDPE and LLDPE geomembranes are two different synthetic liners employed for civil engineering and environmental works in the construction of containment barriers and fluid barriers. While both consist of polyethylene polymers as their basic material with similar advantages they possess differences in terms of molecular structurem physical characteristics, mechanical attributes. For instance HDPE geomembranes have a high tensile strength coupled with rigidity hence can be used in an application that requires strong mechanical properties and stable dimensions. On the contrary however the LLDPE geomembranes have improved flexibility features elongation performance besides being able to resist impacts effectively making them suitable for conformability resilience as well as non-deformation requirements. Thus through understanding these disparities between HDPE and LLDPE geosheets engineers or people who participate in construction initiatives will select materials needed for such enclosures better ensuring optimal results life expectancy cost effectiveness.

- Previous:What is the most widely used geomembranes in current use?

- Next:What is the difference between geotextile and geomembrane?

-

2024-12-05Geomembrane Liners: A Comprehensive Guide