- Understanding the Role of Geomembrane Liners in Waste Management

- Innovations in Geomembrane Liners for Water Management

- Geomembrane Liners: A Comprehensive Guide

- The Future of Geomembrane Liners in Civil Engineering

- Geomembrane Liners: Enhancing Landfill Stability

Manager:Alvin Wang

WhatsApp:+62 8983806051

Tel:+86 10-5797-1075

Email:steelwang@okorder.com

Address:3rd Floor, No.2 Building, No.1 Sanlihe Road

Which is better HDPE geomembrane or polypropylene?

When it comes to containment applications, High-Density Polyethylene (HDPE) geomembrane and polypropylene geomembrane are the materials that most engineers and project stakeholders have to choose between. The two types of materials have their unique properties and benefits which makes the selection process for a preferred type an important step in the planning and design phases of a project. In this article we would make a comparison between hdpe Geomembrane and polypropylene geomembrane to find out which one is most suitable for various containment applications.

Understanding HDPE Geomembrane

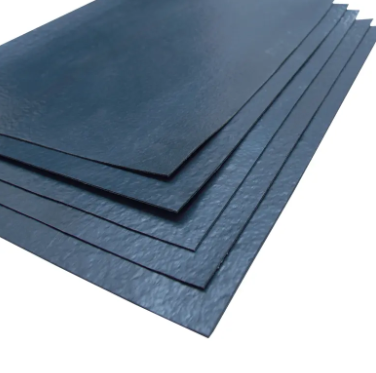

High Density Polyethylene (HDPE) geomembranes are synthetic liners, composed of high-density polyethylene resin. Its thermoplastic nature has made this material famous due to its durability, flexibility, as well as impermeability allowing for its use in many containment applications. Examples of these places where you can find HDPE geomembranes include landfills, ponds, reservoirs, municipal waste water treatment plants etc. Their major role in these areas is preventing leakage of liquid or gas into the environment.

Understanding Polypropylene Geomembrane

On the other hand, polypropylene geomembranes are synthetics liners fabricated from polypropylene resin unlike those made from high density polythene like HDPE geomembranes. Among different types of liner materials used in lagoons such as landfills among others; it offers excellent chemical resistance , mechanical strength and impermeability similar to what HDPE can offer . It is usually found mostly in facilities filled with harsh chemicals or environmental conditions such as mining operations sites or industrial plants located near rivers.

Comparing Properties

In terms of chemical resistance, mechanical strength and impermeability even though both HDPE geomembrane and polypropylene geomembrane appear to be quite similar they differ significantly based on their properties and performance qualities.

1. Flexibility and Durability

For instance, HDPE geomembrane is flexible and strong thus can take the shape of irregular surfaces , move with the land without weak point .On the other hand, polypropylene geomembrane, though also flexible tends to have less flexibility than HDPE geomembrane. However, both are highly durable and survive punctures, tears or UV degradation very well.

2. Temperature Resistance

HDPE geomembranes tend to perform better in terms of temperature resistance as compared to those made from polypropylene. The range of temperatures that it can sustain is quite wide because it can be used across various climates whether cold or hot. For polypropylene however there may be a limitation in its level of temperature resistance especially under extreme heat or cold conditions.

3. Seam Integrity

In containment applications, seam integrity is crucial for the effectiveness of geomembrane liners. HDPE geomembranes are commonly known for their excellent welding performance of seams which creates a leak proof seal since they are usually made so strong that they do not tear apart anyhow while being used.Polypropylene geomembranes may also possess good seam integrity but with varying welding processes and seam strength depending on materials formulations during manufacturing and installation techniques applied.

4. Chemical Resistance

Both HDPE as well as polypropylene geomembranes exhibit high chemical resistance to acids, alkalis solvents hydrocarbons among others. Nevertheless ,the ability for these two materials to resist different chemicals such as acids depends on their compositions including any additives or reinforcements placed within them .

Applications

The choice between HDPE and PP would depend on specific requirements & conditions of containment application: Each type has unique advantages or applications where it may perform better:

- HDPE Geomembrane: Landfills , ponds , reservoirs , wastewater treatment plants – all these different types of containment facilities can use HDPE membranes effectively due to their flexibility, durability as well as temperature resistance to meet various environmental conditions and performance criteria.

- Polypropylene Geomembrane: It is commonly utilized in areas where high chemical resistance is needed such as factories, mines and dangerous waste. This makes it suitable for challenging environments and aggressive substances hence giving it a good mechanical strength and outstanding chemical stability.

Conclusion

In conclusion, the choice between HDPE geomembrane and polypropylene geomembrane depends on the specific requirements and conditions of the containment application. While both materials offer excellent chemical resistance, mechanical strength, and impermeability, they exhibit differences in flexibility, temperature resistance, seam integrity, and other properties. By carefully evaluating the performance characteristics and suitability of each material for the intended application, engineers and project stakeholders can make informed decisions to ensure the effectiveness and longevity of geomembrane liners in containment projects.

-

2024-12-05Geomembrane Liners: A Comprehensive Guide