- Understanding the Role of Geomembrane Liners in Waste Management

- Innovations in Geomembrane Liners for Water Management

- Geomembrane Liners: A Comprehensive Guide

- The Future of Geomembrane Liners in Civil Engineering

- Geomembrane Liners: Enhancing Landfill Stability

Manager:Alvin Wang

WhatsApp:+62 8983806051

Tel:+86 10-5797-1075

Email:steelwang@okorder.com

Address:3rd Floor, No.2 Building, No.1 Sanlihe Road

Which is stronger, HDPE geomembrane or UHMW?

High-Density Polyethylene (HDPE) geomembranes and Ultra-High Molecular Weight Polyethylene (UHMW) are both versatile materials used in various engineering and industrial applications for their strength, durability, and low friction properties. The strength of hdpe Geomembrane and UHMW can be compared by considering several factors such as material composition, molecular structure, mechanical properties, and application-specific requirements. This post looks at the strengths of HDPE geomembrane and UHMW separately along with points to consider when choosing a material for specific applications.

Understanding HDPE Geomembrane

Composition and Properties:

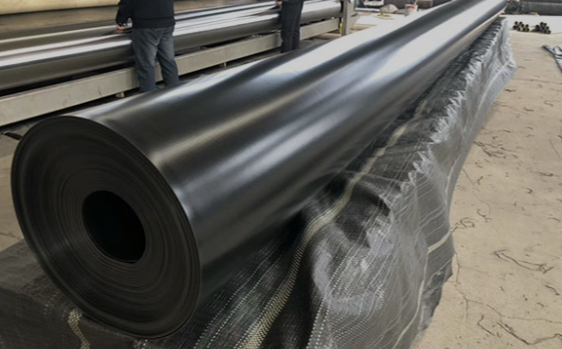

HDPE geomembranes are produced from high-density polyethylene, a thermoplastic polymer that is obtained from ethylene monomer units. For its excellent chemical resistance, durability flexibility as well as impermeability hence making it suitable for containment, fluid barrier or environmental protection purposes. Lined landfills ponds reservoirs water treatment facilities have higher tensile strength of HDPE geomembranes with puncture resistance as well as tear resistance.

Applications:

Due to their versatility and performance characteristics, HDPE geomembranes are extensively used in civil engineering works such as environmental protection activities among others. Common applications for these membranes include landfill liners pond liners reservoir covers secondary containment systems agriculture water storage etcetera. They act as reliable containment solutions that protect harmful substances like hazardous waste industrial chemicals liquids gases from causing pollution thereby safeguarding the environment and human health.

Understanding UHMW

Composition and Properties:

Ultra-High Molecular Weight Polyethylene (UHMW) is a type of polyethylene having extremely long molecular chains thus giving it exceptional strength but also wear resistance while being less abrasive than other materials. High impact strength makes UHMW superior because it has self-lubricating cycle which results in low coefficient of friction allowing sliding whereas HDPE has high wear resistance coefficient. It is also FDA compliant due to its excellent chemical resistance.

Applications:

UHMW material is used across a wide range of industrial and commercial applications where great strength, durability and low friction are required. Examples of such applications include wear strips, guide rails, conveyor components, bearings, bushings, cutting boards as well as marine fender systems among others. Besides being resistant to abrasion impact corrosion and chemicals UHMW exhibits features that make it applicable to different types of equipment.

Strength Comparison

Tensile Strength:

HDPE geomembranes can typically have tensile strengths ranging from 20 MPa to 40 MPa depending on material grade thicknesses manufacturing process used. Meanwhile UHMW typically has higher tensile strength ranging from 25 – 40 MPa making it slightly stronger than HDPE geomembrane in terms of tensile properties.

Impact Strength:

This measures the ability of a material to resist fracture as well as absorb energy under sudden loading conditions or impacts since it is usually measured in Joules per meter (J/m). Therefore, HDPE geomembranes have excellent impact strength depending on the thickness and grade of materials used which range between about 300 J/m up to 800 J/m. However UHMW boasts superior impact strength with values generally ranging from about 500 J/m up reaching even beyond 1500 J/m compared with HDPE geomembrane in terms of its impact resistance characteristics.

Wear Resistance:

This means the ability of a substance to withstand continued use or rubbing against another object without wearing away. The good news is that low friction could be obtained from a HDPE Geomembranes while self-lubrication enables UHMW slide better with less sliding action coefficient. Conveyor systems machine parts and bulk handling equipments would be few examples where such applications are utilized for their sliding rubbing or abrasive wear behaviour.

Chemical Resistance:

Both high-density polyethylene (HDPE) geomembrane and UHMW show some excellent chemical resistance to acids, alkalis, solvents and other corrosive chemicals. HDPE geomembranes are used in various applications for containment of hazardous waste materials, industrial chemicals, and aggressive liquids. UHMW is also unyielding to chemical attack and it has approval from the FDA for food contact as well as beverage manufacturing thus suitable in food processing and pharmaceutical industries.

Material Selection Considerations

Application Requirements:

The specific application requirements such as mechanical properties, chemical resistance, wear resistance and environmental conditions must be taken into consideration when choosing between HDPE geomembrane and UHMW. HDPE geomembranes are great for impermeable containment applications; whereas UHMW is preferred since it offers high impact strength, abrasion resistance and low friction.

Cost Considerations:

When choosing either HDPE geomembrane or UHMW cost is a vital factor. Generally speaking, HDPE geomembranes are more cost-effective than the latter making them popular with budget-conscious projects. However an initial higher cost may be justified by better mechanical properties and performance of UHMW in cases where strongness, longevity or wearability is important.

Environmental Factors:

Performance and service life duration of both HDPE geomembrane or UHMW can be influenced by environmental factors like temperature extremes, UV exposure, as well as chemical exposure. When exposed to UV radiation heat aging or harsh chemicals over time HDPE geomembranes degrade while on its part UHMW shows better resistance against this type of degradation thus keeping its mechanical properties within very broad ranges.

Conclusion

In conclusion both high density polyethylene (HDPE) Geomembrance and Ultra High Molecular Weight Polyethylene (UHMW) have their own set of advantages that make them ideal for engineering industry applications. In terms of impenetrability, chemical resistivity as well as value for money HDPE geomembrance is the best; whereas UHMW has greater strength, impact resistance, and wear resistance properties. In order to determine the most suitable material for a given purpose, one must take into account application-specific requirements, performance criteria, cost considerations and environmental factors when deciding between HDPE geomembrance and UHMW. Finally depending on specific project needs or desired trade-off between toughness, long life span and price HDPE geomembrance or UHMW can be chosen.

-

2024-12-05Geomembrane Liners: A Comprehensive Guide