- Understanding the Role of Geomembrane Liners in Waste Management

- Innovations in Geomembrane Liners for Water Management

- Geomembrane Liners: A Comprehensive Guide

- The Future of Geomembrane Liners in Civil Engineering

- Geomembrane Liners: Enhancing Landfill Stability

Manager:Alvin Wang

WhatsApp:+62 8983806051

Tel:+86 10-5797-1075

Email:steelwang@okorder.com

Address:3rd Floor, No.2 Building, No.1 Sanlihe Road

Which is stronger, HDPE geomembrane or polyethylene?

When choosing materials for critical containment applications, it is important to consider their strength. High-Density Polyethylene (HDPE) geomembrane and polyethylene are both known for being very strong and versatile. But which material is truly the most powerful? In this article we will compare these two contenders based on their qualities of absolute durability and resistance to external impacts.

What is hdpe Geomembrane?

Composition and Characteristics:

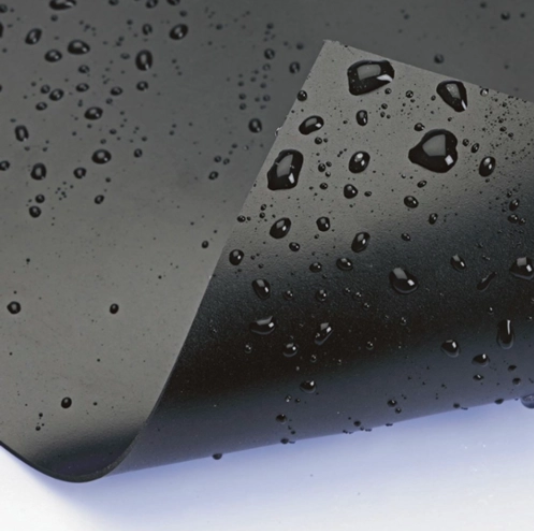

HDPE geomembrane is a kind of polyethylene with high density and molecular structure. It is made by polymerizing ethylene molecules, thus forming thermoplastic material that has high strength, good flexibility as well as chemical resistance. This product finds wide application in civil engineering sphere where it ensures impermeability, reliability and durability.

Applications:

Among various industries using landfill construction materials; mining operations; pond liners systems etc., we can name few examples – secondary containment systems or landfills caps (covers). Such membranes serve as reliable barriers against liquid migration preventing soil pollution through groundwater protection from contamination by chemicals leaking out into the environment or air space above them getting polluted due to gases escaping from below them because they are immune to puncture, tear apart easily under sunlight attack which breaks some bonds holding atoms together thereby creating new weaker ones that can be broken down further through oxidation process facilitated by UV radiation exposure over time leading onto chain scission reaction induced degradation manifesting itself either locally or throughout entire material causing weakening thereof accompanied with loss of mechanical properties resulting in failure.

What Is Polyethylene?

Composition and Characteristics:

Polyethylene stands for thermoplastic polymer derived from ethylene monomers through polymerization process. It can be found in three main forms: high-density (HDPE), low-density (LDPE)and linear low-density (LLDPE). The versatility of this substance is its great feature – it easily processed into various products due to impact resistance properties which make it popular material for packaging industry; on top of that being used widely across different sectors such as construction where strength matters most while automotive sector requires durability.

Applications:

Due to excellent mechanical characteristics displayed by polyethylenes together with good resistance towards chemicals HDPE has found many applications not only in piping systems but also other areas like toys manufacturing or even building houses.

UV resistance is necessary for outdoor applications that are exposed to sunlight for extended periods because they can lead to damage and deterioration. The UV resistance of HDPE geomembrane is natural due to the addition of some components during its manufacture. Conversely, common grades of polyethylene may have to use UV stabilizers or protective coatings so as to minimize the effects of UV degradation thereby complicating matters and increasing costs in a project.

Flexural Strength:

This property measures how well a material resists bending or deforming when subjected to external forces. HDPE geomembrane is usually stronger in flexure than other types of plastic sheets because it has a unique molecular structure and is produced through different processes. Therefore, this feature ensures dimensional stability and integrity where there are folding, dynamic loads or any other kind of bending.

Conclusion

In summary, though both HDPE geomembranes and polyethylenes exhibit admirable strength and durability levels, in containment systems that require critical considerations such as chemical compatibility with stored substances, puncture resistance among others; the former usually performs better than the latter. Its higher tensile strength coupled with impact resistance make it possible for one material alone i.e., High Density Polyethylene (HDPE) Geomembrane Liner which also possesses superior properties like being resistant to most chemicals commonly found within soils; having excellent ultraviolet light protection ability etc., to provide required performance standards under various conditions including long-term service life expectancy requirements etc.. However each one will be suitable depending on particular needs related with environment around worksite as well financial plan limitations involved into realization process.To ensure success and sustainability of their projects, engineers should evaluate strengths & weaknesses inherent within these materials while deciding on what best suits particular situations.

-

2024-12-05Geomembrane Liners: A Comprehensive Guide