- Understanding the Role of Geomembrane Liners in Waste Management

- Innovations in Geomembrane Liners for Water Management

- Geomembrane Liners: A Comprehensive Guide

- The Future of Geomembrane Liners in Civil Engineering

- Geomembrane Liners: Enhancing Landfill Stability

Manager:

WhatsApp:+86 177 0135 2670

Tel:+86 177 0135 2670

Email:marketing@okorder.com

Address:3rd Floor, No.2 Building, No.1 Sanlihe Road

Which is stronger HDPE or Uhmw?

Introduction:

In the realm of geomembranes, particularly in applications like environmental containment and civil engineering projects, the choice between materials can significantly impact the success and longevity of the structure. Among the materials commonly used are high density polyethylene (HDPE) and ultra-high molecular weight polyethylene (UHMW). Both offer distinct advantages, but the question persists: which is stronger?

Understanding Composite Geomembranes:

Before delving into the comparison of HDPE and UHMW, it's essential to understand composite geomembranes. Composite geomembranes combine different materials to leverage the strengths of each component. Typically, these consist of a geomembrane layer, often made of HDPE or UHMW, combined with other layers like Geotextiles or geonets for enhanced mechanical properties and environmental resistance.

Strength of High Density Polyethylene Geomembranes:

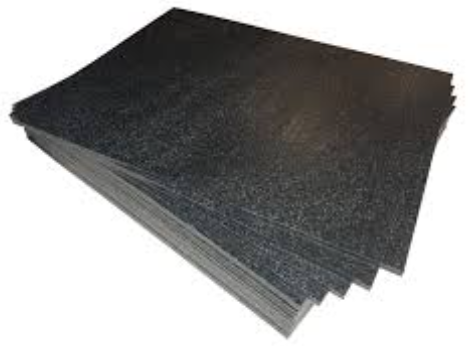

hdpe Geomembranes are renowned for their strength and durability. High density polyethylene, with its strong molecular structure, provides excellent resistance to chemical and environmental stressors. HDPE geomembranes are commonly used in various applications such as landfill liners, mining containment, and pond liners. Their resistance to punctures, tears, and chemical degradation makes them a preferred choice in demanding environments.

Strength of Ultra-High Molecular Weight Polyethylene Geomembranes:

UHMW geomembranes, on the other hand, offer exceptional strength due to their ultra-high molecular weight. UHMW polyethylene boasts one of the highest molecular weights among all polymers, resulting in outstanding abrasion resistance and impact strength. These properties make UHMW geomembranes ideal for applications requiring superior performance against wear and tear, such as in mining operations, marine structures, and hydraulic engineering projects.

Comparative Strength Analysis:

When comparing the strength of HDPE and UHMW geomembranes, several factors come into play. Both materials exhibit high tensile strength, but UHMW tends to outperform HDPE in terms of abrasion resistance and impact strength. In applications where mechanical stresses are a concern, such as in containment systems subject to heavy machinery or abrasive materials, UHMW geomembranes may offer a distinct advantage.

However, HDPE geomembranes excel in puncture resistance and chemical resistance, making them suitable for environments where exposure to harsh chemicals or contaminants is prevalent. Additionally, HDPE geomembranes often provide a more cost-effective solution compared to UHMW, making them a preferred choice for projects with budget constraints.

Environmental Considerations:

In addition to strength and durability, environmental factors play a crucial role in material selection for geomembranes. Both HDPE and UHMW exhibit excellent resistance to environmental degradation, including UV radiation and chemical exposure. However, HDPE geomembranes may be more susceptible to oxidative degradation over time compared to UHMW, particularly in applications with prolonged exposure to sunlight.

Furthermore, the manufacturing processes of HDPE and UHMW can impact their environmental footprint. HDPE is more commonly recycled and has a well-established recycling infrastructure, making it a more sustainable choice in terms of end-of-life disposal. UHMW, while recyclable, may present challenges in recycling due to its ultra-high molecular weight and specialized processing requirements.

Application-Specific Considerations:

Ultimately, the choice between HDPE and UHMW geomembranes depends on the specific requirements of the application. For projects where abrasion resistance and impact strength are paramount, such as in mining or hydraulic structures, UHMW geomembranes may offer superior performance. Conversely, for applications where puncture resistance and chemical compatibility are critical, such as in hazardous waste containment or chemical storage facilities, HDPE geomembranes may be the preferred option.

Conclusion:

In the debate over which is stronger between HDPE and UHMW geomembranes, the answer largely depends on the specific demands of the application. While both materials offer high strength and durability, their performance varies in terms of abrasion resistance, impact strength, puncture resistance, and chemical compatibility. By carefully evaluating the requirements of the project and considering factors such as environmental considerations and budget constraints, engineers and designers can make informed decisions to ensure the long-term success and integrity of geomembrane applications."

- Previous:What is the impact factor of geotextile and geomembrane?

- Next:What are the three types of geotextile fabric?

-

2024-06-13Geomembrane is not plastic cloth