- Understanding the Role of Geomembrane Liners in Waste Management

- Innovations in Geomembrane Liners for Water Management

- Geomembrane Liners: A Comprehensive Guide

- The Future of Geomembrane Liners in Civil Engineering

- Geomembrane Liners: Enhancing Landfill Stability

Manager:Alvin Wang

WhatsApp:+62 8983806051

Tel:+86 10-5797-1075

Email:steelwang@okorder.com

Address:3rd Floor, No.2 Building, No.1 Sanlihe Road

Why is HDPE geomembrane waterproof?

HDPE or high-density polyethylene is composed of a number of thermoplastic polymers generally known for their strong molecular structure and resistance to liquids and gases. These qualities have made them popular as waterproof liners in various industries including construction, environmental protection among others. But what makes this material able to resist water so effectively?

Composition – High-Density Polyethylene (HDPE)

These geomembranes are made up mostly by weight from high density polyethylenes, which means they contain many more molecules than some other plastics like LDPEs(low). This characteristic alone gives them better chemical resistance against solvents such as acetone.

Molecular Structure and Chain Packing

The structure of HDPE compared to LDPE is highly linear with closely packed chains that are less branched. Due to this kind of packing there will be fewer gaps between the molecules thus preventing water permeation through those spaces; instead it moves along these tightly woven structures until it finds an exit point outwards from liner wall or bottom surface into surrounding soil or groundwater.

Crystalline Structure vs Amorphous Regions

Some parts of these materials have an ordered arrangement while others do not show any particular pattern at all called crystallinity versus amorphousness respectively. The former contributes greatly towards mechanical strength where as latter provides flexibility making them ideal candidates for applications requiring both properties simultaneously.

Thermal Stability/Resistance To Degradation

Another important aspect about HDPEs’ ability to act against moisture intrusion lies within its exceptional stability over a wide range temperatures especially below 180 degrees Celsius; this is because during heating process when melting occurs most substances tend becoming chemically reactive but here they remain inert thus making them best suited where exposure UV radiations become inevitable coupled with harsh chemicals presence. They also exhibit great resistance towards degradation brought about by environmental factors like heat aging, ultraviolet light exposure among others hence can be relied upon for long-term performance without failure.

Manufacturing Process and Quality Control

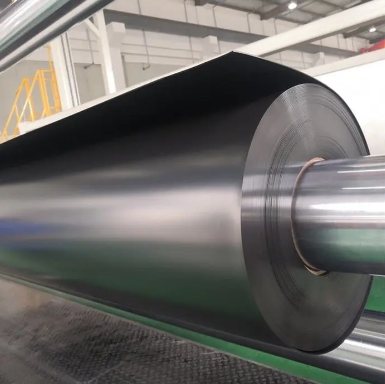

There are different ways through which these geomembranes can be manufactured depending on intended use or end product desired by client. For instance, extrusion coating method involves melting resin pellets followed immediately by cooling them down into thin sheets while calendering technique requires passing molten material between two or more rolls having engraved designs at specific temperatures until required thickness achieved. In either case strict supervision should be exercised during production stages such as monitoring temperature variations throughout entire line length; ensuring uniformity thicknesses across width etcetera so that final outcome becomes effective against water penetration wherever employed.

Seaming /Welding Techniques

Apart from being inherently impenetrable below certain levels of pressure head difference across liner thickness, joints need to be created where individual panels meet each other together with penetrations made through walls bottoms tanks ponds etc. This way continuity maintained along perimeter corners otherwise there would exist points weakness allowing entry fluids into adjacent regions leading contamination.

Specific Applications Consideration

While these liners have proven themselves over years being permanently impervious water under normal conditions some factors may affect their performance in certain applications. Construction methods used during installation process like anchoring systems chosen; soil type encountered at site; chemicals stored proximity among many others could influence how well it prevents liquid migrations through its body hence must not ignored instead taken into account when designing structures requiring retention containment liquids hazardous nature.

Conclusion

In summary, this paper has discussed HDPEs as good materials for preventing moisture intrusion but why are they so? What makes them unique here is the number of molecules present within given mass compared to other types plastics this alone provides better chemical resistance against solvents like acetone. Also due closer packing less branching fewer gaps exist between adjacent molecules thus no space left for fluid permeation except along tightly woven chains which act as paths resistance towards water flow through liner material.

Secondly, there exists an orderly part called crystalline region characterized by close packing uniform arrangement while remaining portions appear random without any specific pattern known amorphous area; weneed both flexibility and mechanical strength simultaneously hence these are ideal candidates designed have such different properties at same time.

Thirdly, they can withstand various environmental conditions UV radiations coupled with harsh chemicals presence because have superior stabilities over wide temperature ranges below 180 degrees Celsius; most substances become reactive during heating process but not them.

Fourthly, various manufacturing methods used depending on application required thus should always be closely watched every step to ensure desired outcomes achieved against moisture penetration wherever applied.

Finally, joints created between adjacent panels should maintain continuity corners otherwise infiltration will take place so easily at such points therefore need for proper seaming/welding techniques in all critical regions like intersections tanks bottoms walls etcetera

By adopting state-of-the-art production methods, strict inspection system and rigorous installation procedures, plastic geomembrane made of high-density polyethylene can achieve the best effect of waterproofing which protects infrastructures, safeguards ecological balance and guarantees the durability of containment structures for many years. With increasing requirement for impermeable materials spanning various sectors, high-density polyethylene (HDPE) geomembranes still take a leading position because they are considered to be most dependable when it comes to preventing water from coming in or out.

-

2024-12-05Geomembrane Liners: A Comprehensive Guide