- Understanding the Role of Geomembrane Liners in Waste Management

- Innovations in Geomembrane Liners for Water Management

- Geomembrane Liners: A Comprehensive Guide

- The Future of Geomembrane Liners in Civil Engineering

- Geomembrane Liners: Enhancing Landfill Stability

Manager:

WhatsApp:+86 177 0135 2670

Tel:+86 177 0135 2670

Email:marketing@okorder.com

Address:3rd Floor, No.2 Building, No.1 Sanlihe Road

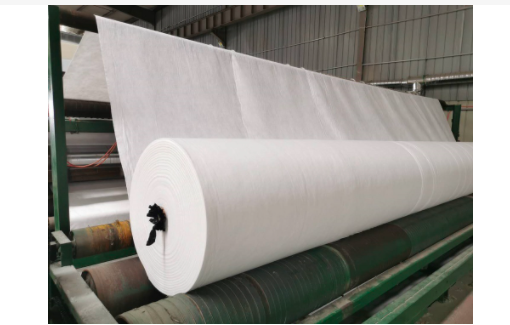

Woven and Non-woven Geotextile Fabrics In Construction: A Harmonious Blend

Woven and non-woven geotextile fabrics are the symphony of strength and flexibility in the complex world of construction and environmental engineering. These are silent partners that help us in building strong, durable and ecofriendly infrastructures. This article pays homage to woven, as well as non-woven Geotextiles by exploring their unique features, uses and the connection they create between constructors and constructed environment.

The Woven Mastery: A Tale of Strength and Structure

For heavy duty applications where it is difficult to interlace individual threads in a very robust textile, woven geotextile fabric is carefully crafted with an apparent perfection. Basically used for road works, driveways or high ways where reinforcement is particularly important for stabilization purposes due to its high tensile stress. Although woven geotextile fabric may not be suitable for any drainage projects because of its low permeability, yet it excellently performs this function over time; separation/reinforcement properties and resisting corrosion among others make it a good foundation material.

The Non-Woven Essence: Filtration And Flexibility

Nonwoven geotextile fabric is adaptable to topography as it may be needle punched or bonded in other ways. Thus made from synthetic fibers like polyester or polypropylene etc., this felt-like material allows both water movement through itself as well as filtration systems to operate optimally. It’s ideal for protection against erosion sites that require separation or drainage due to the fact that it has excellent soil retention together with high water flow rates.

Applications in Civil Engineering: A Spectrum of Uses

Different civil engineering projects across the board are where woven/non-woven geotextiles find their application. For instance, woven geotextiles have been applied in reinforcing roads/slopes/walls/foundations because they have great resistance levels against breaking and an ability to permanently deform. Non-woven geotextiles are ideal for projects that require protection from soil contamination as well as efficient water control because of their superior filration capabilities.

Durability and Environmental Considerations: A Sustainable Choice

Woven geotextiles are always long lasting materials, making them highly appropriate for sustainable projects. On the other hand, non-woven geotextiles can be made from biodegradable materials thereby providing an eco- friendly choice. They also have high resistance to tearing and puncturing which makes them preferred in different environmental conditions due to their chemical stability.

The Economical Balance: Cost and Performance

The cost effectiveness of geotextile fabrics is a significant factor to take into account. Although woven textiles tend to be more expensive initially because they are stronger and longer lasting, this increases their lifespan while reducing maintenance costs hence making it cheaper in the long run. On the other hand, non-woven geotextiles come at a lower price which allows one to get a budget option for those situations where great strength is not primarily required.

Installation and Maintenance: A Seamless Integration

How these fabrics are put up affects their functionality significantly. In difficult environments where installation needs to be done carefully, woven geotextiles on the one hand have a sturdy structure whereas non-wovens on the other hand are flexible enough to adapt themselves onto different landscapes. Proper installation helps ensure that minimal maintenance costs can achieve intended functions like separation, filtration or even reinforcement by such textile materials used as they were meant to work when installed properly in place.

The future of geotextile fabrics: Innovations and Sustainability.

Geotextile fabric development in the construction industry is increasingly moving towards strong and functional materials with low environmental impact. The development of manufacturing technology and material selection is leading to improved performance of such fabrics as well as their reduced environmental impact.

Conclusion: A Textile Leading to Progress and Conservation

To conclude, woven and non-woven geotextiles are key components within the construction and environmental sectors. This culminate into healthy infrastructure for which these unique characteristics and uses play a vital role. However, usage of geotextile fabrics would still remain an anchor point even when new materials or technologies emerge since we are committed towards a better planet free from pollution.

A symbol for our forwardness in progressiveness and preservation, both woven or non-woven geotextile fabrics are more than just construction materials. These express our corporate culture that has made us to pull together as clients in these projects leading to creation of many jobs for ourselves. For instance, we can use this type of fabric in project management where it will help; let’s say first course students learn about a concrete course at the University thereby developing necessary skills required before assuming leadership roles later on upon graduation. As such, there is need for interweaving these two types of geotextiles within our projects which will ensure that they are strong but also environment friendly in nature.

- Previous:The Canvas of Construction: Unraveling the Promise of Geotextile Paper

- Next:Embracing the adaptability of geotextile landscape fabric in gardening and beyond