- Understanding the Role of Geomembrane Liners in Waste Management

- Innovations in Geomembrane Liners for Water Management

- Geomembrane Liners: A Comprehensive Guide

- The Future of Geomembrane Liners in Civil Engineering

- Geomembrane Liners: Enhancing Landfill Stability

Manager:Alvin Wang

WhatsApp:+62 8983806051

Tel:+86 10-5797-1075

Email:steelwang@okorder.com

Address:3rd Floor, No.2 Building, No.1 Sanlihe Road

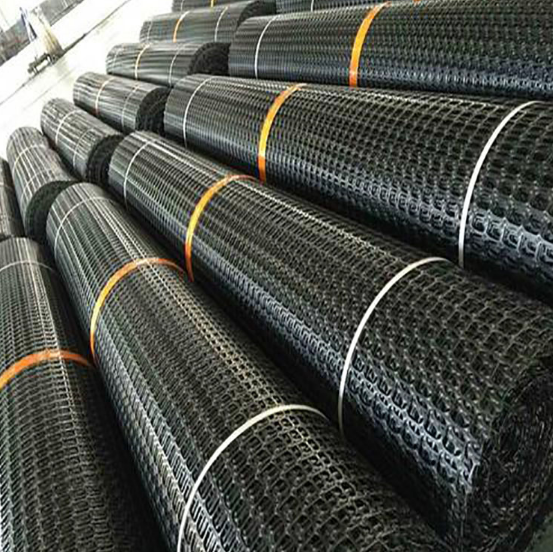

Application of geogrid reinforcement construction technology

A certain highway section is a mountainous highway. Due to the terrain restrictions during the construction process, the roadbed width of this section is relatively narrow and cannot meet the construction requirements. According to the actual situation, in order to ensure the smooth progress of the roadbed widening project, the road section needs to be reasonably designed and optimized. Through the analysis of the geological conditions of this highway section, it can be found that the roadbed of this highway section is mainly silt roadbed. According to the roadbed stability requirements, this section of the highway needs to be widened. In order to ensure the stability of this road section, geogrid reinforcement construction technology can be used to improve the stability of the roadbed.

1 Preparation work before construction

-

Strengthen the inspection and treatment of roadbed. The subgrade should be inspected to see if there are any problems such as cracking, misalignment, collapse, uneven settlement, etc. The stability of the subgrade should also be checked to ensure that the stability of the subgrade meets the design requirements.

-

Choose the appropriate geogrid. The type of geogrid should be selected according to the actual conditions of the project and reasonably arranged.

-

Do a good job in construction setting out. First, according to the actual conditions of the construction site, lay the geogrid in accordance with the design requirements; secondly, measure the length, width, elevation and other data; finally, after the geogrid is laid, conduct timely inspection and acceptance to ensure that the geogrid after laying is The gate can meet the actual needs of the project.

2 Geogrid laying requirements The basic requirements for geogrid laying are as follows

-

Clean the original road surface and make corresponding preparations. Before the roadbed widening construction, the original road surface should be cleaned to ensure its construction quality. At the same time, a combination of manual and mechanical methods should be used during construction.

-

Geogrid inspection. When laying geogrids, they should be inspected to ensure that their flatness and verticality meet the requirements of construction standards.

-

Clean the paving area. Before laying the geogrid, the original road surface should be cleaned and debris, etc. should be cleared away.

-

When laying geogrids, relevant regulations should be strictly followed. Normally, geogrids are laid at a height of approximately 20 cm.

-

Geogrid laying should be carried out from the foot of the subgrade slope to the road arch, and distortion should be avoided as much as possible.

-

Set 20 cm wide overlapping edges at the ends and middle of the geogrid. The overlapping edges should be kept flat and perpendicular to the direction of the road arch.

-

During the roadbed widening construction process, in order to reduce the uneven settlement between the new and old pavements, a layer of geogrid can be set between the old and new pavements. When laying the geogrid, ensure that it has good flatness; its overlapping edges need to be kept flat and perpendicular to the direction of the road arch.

-

During the highway widening construction process, if large pieces of garbage, stones and other debris are encountered, they must be cleaned up in time.

-

When laying geogrids, construction workers should fix them on the road arch in accordance with relevant regulations, tighten, straighten and fix them. At the same time, they should clean up debris, dust, etc. on the surface of the geogrids.

-

After the geogrid is laid, it should be properly compacted, and a certain distance should be maintained between it and the original road surface during the compaction process.

3 Filling of filler

-

Filling requirements Generally, lime soil, gravel soil and plain fill soil are used as fillers. Filling can only be carried out when the moisture content of the filler reaches the optimal state. When filling the filler, the base treatment must first be carried out. Secondly, before filling the filler, the moisture content of the filler should be tested, and the optimal moisture content should be determined based on the test results.

-

Geogrid laying When laying geogrids, control the overlap length to about 30 cm, and ensure that the overlap length between each layer is not less than 10 cm. Generally, each layer of geogrid needs to be laid to the design elevation before it is laid. And in order to ensure that the construction quality of the roadbed project is effectively improved, the construction workers also need to set the overlapping part into a slope shape to facilitate mechanical construction.

-

Geogrid installation Before installing the geogrid, its surface should be cleaned and ensured that it is dry. When installing the geogrid, it must be ensured that the geogrid has sufficient strength and stiffness [5]. Therefore, construction personnel need to densify the longitudinal overlap of the geogrid, and also need to control the overlap length.

-

Geogrid embankment filling In the filling of geogrid embankment, the layered filling method should be used to fill the filler. In order to ensure the quality and efficiency of the filling, the construction personnel also need to ensure the filling quality. Moisture content is at its best. When filling, the thickness should be controlled to ensure that the thickness between each layer is less than 30 cm.

-

Subgrade drainage When designing the subgrade drainage system, construction workers also need to set up a corresponding drainage system at the bottom of the subgrade. Under normal circumstances, construction workers can use seepage ditches or interception ditches to design and construct subgrade drainage systems. In addition, after the roadbed construction is completed, inspection and acceptance work should be carried out in a timely manner to ensure that the roadbed project can effectively extend its service life after being put into use.

4 Reinforcement construction

-

Construction plan design Before carrying out widening and reinforcement construction, detailed construction plan design is required, including determining the scope and size of widening, selecting appropriate geotechnical materials and reinforcement methods, etc.

-

Subgrade preparation Before widening and reinforcing construction, the original subgrade needs to be cleaned and processed to ensure that the subgrade surface is smooth and free of debris and potholes.

-

Reinforcement material selection Select appropriate geotechnical materials as reinforcement materials. Common materials include geogrids, Geotextiles, etc. Select appropriate reinforcement materials based on actual conditions and design requirements.

-

Reinforcement construction method: According to the design requirements, the reinforcement materials are laid on the surface of the roadbed and fixed. Common reinforcement construction methods include laying geogrids, burying geotextiles, etc.

-

Reinforcement layer thickness and density Determine the thickness and density of the reinforcement layer according to the design requirements. The thickness and density of the reinforcement layer should meet the design requirements to ensure the reinforcement effect.

-

Construction quality control During the construction process, quality control must be carried out, including quality inspection of reinforcement materials, testing of reinforcement layer thickness and density, etc., to ensure that the construction quality meets the requirements.

- Previous:The role of geogrid reinforcement construction technology in widening highway subgrade

- Next:What is HDPE geomembrane?