- Understanding the Role of Geomembrane Liners in Waste Management

- Innovations in Geomembrane Liners for Water Management

- Geomembrane Liners: A Comprehensive Guide

- The Future of Geomembrane Liners in Civil Engineering

- Geomembrane Liners: Enhancing Landfill Stability

Manager:

WhatsApp:+86 177 0135 2670

Tel:+86 177 0135 2670

Email:marketing@okorder.com

Address:3rd Floor, No.2 Building, No.1 Sanlihe Road

The Strengthening Vertebrae: Tensar Geogrids in Civil Engineering Miracles

In civil engineering’s complex dance, Tensar geogrids have been the unsung heroes of reinforcement in the merging of soil with structure. As an innovative engineer, I have witnessed firsthand the transformative influence that Tensar geogrids possess, which is a story I am enthusiastic about sharing. A narrative on this article is made up of durability, performance and sustainability as threads intertwined together to give tribute to resilience and strength brought to infrastructure by Tensar Geogrids.

Understanding What Makes Tensar Geogrids Tick

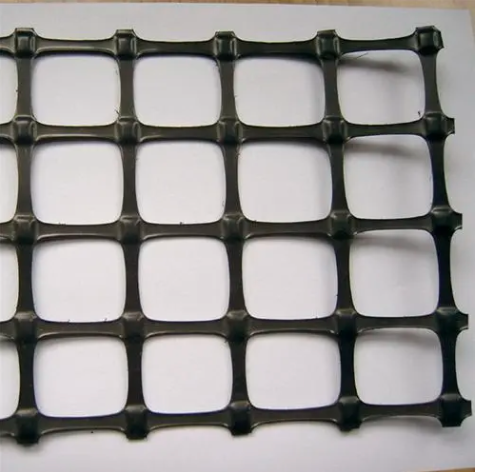

Tensar geogrids are more than mere polymer grids; they embody strength and reliability for geotechnical engineering. The geogrids are manufactured from high-density polyethylene (HDPE), or polypropylene (PP), which gives them an ability to defy time through providing unmatched stiffness, strength and durability. These tensile elements or ribs form a strong grid system whose integral connection forms a roll that can be used in a number of applications.

The Adaptable Range of Tensar Geogrids

The adaptability of Tensar geogrids remains their most fascinating attribute. In the construction world, they can be said to be jack-of-all-trades since they can handle any work such as road construction and railway embankments among others like slope reinforcement and foundation support. This flexibility signifies the creative design behind Tensar geogrids, enabling them to reinforce soils or aggregate materials by enhancing their properties that ensure stability and life longevity.

Harmony of Reinforcement: How Do They Work?

Interlocking and confinement create the reinforcement mechanism for tensar-geosynthetics. Between the ribs there exist openings or apertures that enable aggregates to interlock with geo-grids thus forming new composite materials with increased strength and deformability. Load transfer from the soil to geo-grid is made possible by this interlocking effect that allows geo-grids to carry high loads throughout the service life of a structure, often up to 120 years.

The NextGen Frontier: Tensar® InterAx® Geogrids

Tensar geogrids New generation known as Tensar® InterAx®, have become an epitome of geogrid technology. These advanced geosynthetics are aimed at enhancing the performance of roads, railways and other traffic areas. The unique geometry of the InterAx® geogrids has increased their interaction with granular materials leading to better mechanical stabilization layer. This innovation not only improves the load-bearing capacity but also contributes to sustainability by reducing construction time and material requirements.

Sustainability in Reinforcement: Tensar HX® Geogrids

In terms of geosynthetics sustainability, Tensar HX® geogrids are like a shining light in darkness. These are supported by Environmental Product Declaration (EPD) which makes them first post-industrial product offering by Tensar showing their environmental benefits. Designed for use with a wide range of aggregates, Tensar HX Geogrids provide cost savings as well as ecological advantages on a project-by-project basis.

Various Applications and Success Stories

There are many successful projects worldwide that have used Tenstar’s geogrids. Different soil reinforcement scenarios including American busy highways and quiet European railway tracks have seen Tenstar’s geogrids come out strongly as winners thus proving their efficacy. Cost effectiveness and simple installation process were mentioned as some of their merits by customers who have praised these products reliability and performance in respective success stories regarding Tenstar’s GEOGRIDS.

THE EMOTIONAL CONNECTION: My Journey with Tensar Geogrids

There is an emotional connection that comes with working for Tensar geogrids. Every project is a child of mine and seeing it come from nothing more than a drawing to a solid structure with support from Tensar geogrids fills me with pride. The process is slow but sure, just like the infrastructure takes years to grow into part and parcel of Mother Nature.

THE FUTURE OF TENSR GEOGRIDS: A PROMISING HORIZON

The future of tensar geogrids is as hopeful as the horizon after storm subsides. As we strive to adapt to climate change and environmental destruction, there has never been such a pressing need for effective and sustainable soil reinforcement solutions. Tensar geogrids offer an eco-friendly cost-effective long lasting alternative that can be customized in line with particular needs of any development.

To sum up, without making noise or uttering even a word, Tensar geogrids formed the backbone of strength in civil engineering sector. They have become indispensable tools in any engineer’s arsenal because they provide multidirectional reinforcement and stabilization services. With further innovations and explorations on the way forward, Tensar geogrids are poised for playing even bigger roles in infrastructure development thereby consolidating their place as major components of soil reinforcement/ stabilization activities.

- Previous:Biaxial geogrids in modern infrastructure: a versatile role

- Next:The Silent Guardians: The Unseen Strength of Geomembrane Liners