- Understanding the Role of Geomembrane Liners in Waste Management

- Innovations in Geomembrane Liners for Water Management

- Geomembrane Liners: A Comprehensive Guide

- The Future of Geomembrane Liners in Civil Engineering

- Geomembrane Liners: Enhancing Landfill Stability

Manager:

WhatsApp:+86 177 0135 2670

Tel:+86 177 0135 2670

Email:marketing@okorder.com

Address:3rd Floor, No.2 Building, No.1 Sanlihe Road

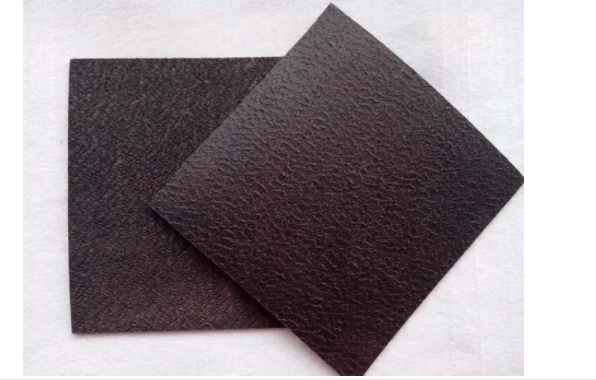

Texture’s Power: Exploring the Role of Textured Geomembrane in Modern Engineering

Among geosynthetic applications, textured geomembranes remain silent and provide a resilient bond to soil that keeps engineering structures intact. Whether it is mining in high stakes environment or constructing landfills and reservoirs, interface strength between textured geomembrane and soil is one of the critical factors that determine the success of these projects. This article examines textured geomembranes addressing their applications, significance of their interface strength and innovative tests validating their performance.

The Role of Textured Geomembrane in Mining

Textured High-Density Polyethene (HDPE) geomembranes play an important role in the mining industry where environmental responsibility is key and impacts can be profound. These geomembranes are known for their uniform asperity height due to flat-die manufacturing process. For instance, direct shear tests on such interfaces reveal consistent peak resistance and residual resistance values regardless of asperity height particularly when working on bauxite projects.

The Significance of Interface Shear Strength

Interface shear at soils-geomembrane interfaces are vital for designing slopes lined with geomembranes in landfill sites, reservoirs, or canals. Experimental documentation on interaction behavior between various soils and different types of geomembranes improves reliable design and construction for such applications. Research has established that sub-angular sand grains; soft GMs; rough GM surfaces mobilize interface shear resistance more effectively.

Geomembrane-Soil Interface: A Focus on Textured Characteristics

Consequently, while asperities height on textured GMs does not significantly affect interfacial parameters’ other texture characteristics could be more significant. The need for further evaluations into this facets to improve this strength is thus underscored by this finding. Thus there is a strong case for testing geosynthetic/soil interfaces within a liner project carried out by a mining company based.

The Influence of Texture on Interface Behavior

Research is ongoing concerning the change pattern in geomembrane surface roughness with respect to geotextile/textured geomembrane interfaces. The understanding of how these patterns affect the interface can enhance design and performance of GM systems. This underscores the importance of performing GM/soil interface tests for any liner project, particularly in mining.

Testing and Evaluation: A Pragmatic Approach

Textured geomembranes are evaluated through a variety of tests that measure properties such as asperity height, core thickness, density, tensile properties, tear resistance and puncture resistance. Standard test methods described by ASTM International provide a comprehensive framework for assessing the physical and mechanical characteristics of these geomembranes.

Standardization and Quality Assurance

Quality and consistency in production are maintained through standards such as ASTM D7466 on measuring asperity height or ASTM D5994 for textured geomembranes’ core thickness. Again, carbon black content determination tests with regard to oxidative induction time and shear strength of soil-geosynthetic interfaces are used in proper evaluation of geomembrane performance.

The Future of Textured Geomembrane Applications

In response to growing need for sustainable and reliable solutions using geosynthetics, there will be an expansion in the use of textured geomembranes. Advancements in material science plus engineering may lead to improved textures having more superior interface strengths and durability.

The future of textured geomembranes lies in embracing innovative breakthroughs that enhance their soil interface to withstand environmental strains and adapt to different uses, among them are new manufacturing techniques and materials with superior performance metrics.

In conclusion; the enduring impact of textured geomembrane

Textured geomembranes are an essential part of modern geosynthetic engineering applications. They bond well with soils, guaranteeing stability and long life for critical infrastructure projects. As we forge ahead in our quest for a safer planet, the use of textured geomembranes in environmental protection and construction will only grow further, thereby providing a sustainable reliable solution for engineering problems.

The textured geomembrane with its improved interfacial strength is a testament to our commitment to developing a strong shield against our environment. These materials are not merely commodities; they are hope towards what tomorrow might be like – one where our concern for the earth’s safety and progress converge. The textured geomembrane is a warm embrace from human cleverness that encircles the globe guaranteeing its safety, keeping it secure as well as cherished. The existence of such materials that promise durability plus defence emphasizes how great possibilities lie within human inventiveness towards achieving an improved future.

- Previous:Layfield Geomembrane: A Living Shield for the Environment, A Promise for the Future

- Next:Venta de Geomembrana: Revealing the Protective Nature of Textured Geomembrane Solutions