- Understanding the Role of Geomembrane Liners in Waste Management

- Innovations in Geomembrane Liners for Water Management

- Geomembrane Liners: A Comprehensive Guide

- The Future of Geomembrane Liners in Civil Engineering

- Geomembrane Liners: Enhancing Landfill Stability

Manager:

WhatsApp:+86 177 0135 2670

Tel:+86 177 0135 2670

Email:marketing@okorder.com

Address:3rd Floor, No.2 Building, No.1 Sanlihe Road

How is geomembrane manufactured?

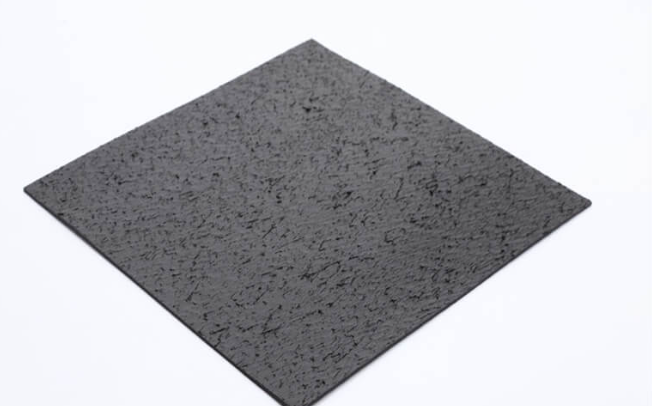

Geomembranes are essential components in various civil engineering, environmental, and geotechnical applications. These impermeable sheets play a crucial role in containment, fluid barrier systems, and environmental protection. Among the different types available, composite geomembranes and high-density polyethylene (HDPE) geomembranes stand out for their durability, flexibility, and resistance to various environmental conditions. But how are these geomembranes manufactured? Let's delve into the intricate process behind the production of composite geomembranes and hdpe Geomembranes.

Understanding Composite Geomembranes

Composite geomembranes are engineered materials that combine multiple layers to achieve specific performance characteristics. Typically, a composite geomembrane comprises a geomembrane liner and a geotextile layer bonded together. The geomembrane provides impermeability, while the geotextile enhances strength, puncture resistance, and frictional properties.

1. Geotextile Production

The manufacturing process of composite geomembranes begins with the production of the geotextile layer. Geotextiles are usually made from synthetic polymers such as polypropylene, polyester, or polyethylene. The polymer fibers are extruded, spun, and then woven or non-woven into a fabric structure. The geotextile layer provides reinforcement and filtration properties to the composite geomembrane.

2. Geomembrane Extrusion

Simultaneously, the geomembrane layer is produced through an extrusion process. In the case of composite geomembranes, the geomembrane is typically made of HDPE, LDPE (low-density polyethylene), or LLDPE (linear low-density polyethylene). The polymer resin is melted and extruded through a flat die to form a continuous sheet of geomembrane. This sheet is then cooled and rolled onto large spools.

3. Bonding Layers

Once the geotextile and geomembrane layers are produced, they are combined through a bonding process. The bonding can be achieved through various methods such as heat lamination, adhesive bonding, or needle punching. Heat lamination is a common technique where the layers are pressed together and heated to create a strong bond. Adhesive bonding involves applying a specialized adhesive between the layers, while needle punching mechanically interlocks the fibers of the geotextile with the geomembrane.

Production of High-Density Polyethylene (HDPE) Geomembranes

HDPE geomembranes are single-layer impermeable sheets manufactured solely from high-density polyethylene resin. HDPE geomembranes are known for their excellent chemical resistance, durability, and flexibility, making them suitable for a wide range of applications, including waste containment, water storage, and mining operations.

1. Polymer Resin Preparation

The production of HDPE geomembranes begins with the preparation of the polymer resin. High-density polyethylene resin is derived from ethylene monomer through a polymerization process. The resin is then compounded with additives such as antioxidants, UV stabilizers, and processing aids to enhance its performance and durability.

2. Extrusion Process

Once the polymer resin is prepared, it undergoes an extrusion process to form the geomembrane sheet. The resin pellets are fed into an extruder, where they are melted and homogenized under high temperature and pressure. The molten HDPE is then extruded through a flat die to produce a continuous sheet of geomembrane with uniform thickness and width.

3. Cooling and Sizing

After extrusion, the HDPE geomembrane sheet is cooled using a series of rollers or water baths to solidify the molten polymer. The cooled sheet is then trimmed and cut to the desired width and length. Quality control measures are implemented throughout the process to ensure that the geomembrane meets the specified thickness, density, and mechanical properties.

Conclusion

The manufacturing process of composite geomembranes and HDPE geomembranes involves intricate procedures and specialized equipment to produce high-quality impermeable liners. Composite geomembranes combine the strength and filtration properties of geotextiles with the impermeability of geomembranes, making them ideal for various containment applications. On the other hand, HDPE geomembranes offer excellent chemical resistance and durability as single-layer sheets. Understanding the manufacturing process behind these geomembranes provides insights into their performance and suitability for different engineering and environmental projects."

-

2024-06-13Geomembrane is not plastic cloth