- Understanding the Role of Geomembrane Liners in Waste Management

- Innovations in Geomembrane Liners for Water Management

- Geomembrane Liners: A Comprehensive Guide

- The Future of Geomembrane Liners in Civil Engineering

- Geomembrane Liners: Enhancing Landfill Stability

Manager:

WhatsApp:+86 177 0135 2670

Tel:+86 177 0135 2670

Email:marketing@okorder.com

Address:3rd Floor, No.2 Building, No.1 Sanlihe Road

What is geomembrane material?

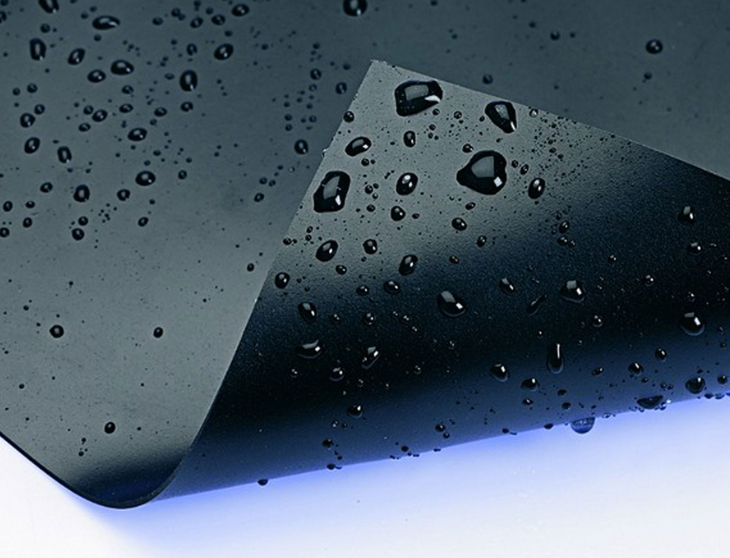

Geomembranes play a crucial role in modern engineering and environmental protection efforts. These impermeable membranes are designed to contain liquids and gases in a variety of applications, ranging from landfills to water containment systems. Among the various types of geomembranes available, composite geomembranes and high-density polyethylene (HDPE) geomembranes stand out for their versatility and durability.

Understanding Composite Geomembrane

Composite geomembranes are engineered materials comprised of multiple layers, each serving a specific purpose to enhance overall performance. Typically, a composite geomembrane consists of a geomembrane layer combined with one or more geotextile or geonet layers. This combination offers superior strength, puncture resistance, and environmental protection compared to single-layer geomembranes.

The geomembrane layer in a composite geomembrane is often made of materials such as HDPE, LDPE (low-density polyethylene), PVC (polyvinyl chloride), or EPDM (ethylene propylene diene monomer). These materials provide excellent chemical resistance and impermeability, essential properties for containment applications. Additionally, the selection of geomembrane material depends on factors such as the type of containment, environmental conditions, and regulatory requirements.

Enhanced Properties of Composite Geomembranes

The incorporation of geotextile or geonet layers into composite geomembranes imparts several benefits. Geotextiles, typically made of woven or non-woven polypropylene or polyester fibers, enhance filtration, drainage, and protection against punctures. Geonets, on the other hand, are three-dimensional structures made of polymer materials, providing additional cushioning and drainage capabilities.

By combining different materials and layering techniques, composite geomembranes offer enhanced properties such as increased tensile strength, tear resistance, and dimensional stability. These features make them suitable for a wide range of applications, including landfill liners, pond liners, secondary containment systems, and mining operations.

Applications of Composite Geomembranes

Composite geomembranes find extensive use in various industries and environmental projects due to their versatility and reliability. In landfill applications, they serve as primary and secondary liners, preventing leachate contamination and protecting the surrounding soil and groundwater from pollutants. The composite structure ensures long-term performance under the harsh conditions found in landfill environments.

In mining operations, composite geomembranes play a critical role in containment systems for tailings ponds and heap leach pads. Their robust construction and chemical resistance safeguard the environment against the release of toxic substances and acidic solutions. Additionally, composite geomembranes are employed in wastewater treatment facilities, agricultural ponds, and industrial containment facilities, where they provide effective containment and environmental protection.

Introduction to High Density Polyethylene Geomembrane

High-density polyethylene (HDPE) geomembranes are a type of geomembrane renowned for their strength, flexibility, and chemical resistance. Manufactured from high-density polyethylene resins, these geomembranes offer exceptional durability and longevity in various applications. hdpe Geomembranes are produced through a process of extrusion, which results in a smooth, uniform membrane with consistent mechanical properties.

Properties of High Density Polyethylene Geomembranes

HDPE geomembranes exhibit several key properties that make them ideal for containment applications. Their high tensile strength and puncture resistance ensure reliable performance in demanding environments. HDPE geomembranes also possess excellent resistance to chemical and biological degradation, making them suitable for containing hazardous substances and wastewater.

Furthermore, HDPE geomembranes are highly flexible, allowing for easy installation over irregular surfaces and terrain. This flexibility, combined with their ability to withstand temperature fluctuations and UV exposure, ensures long-term integrity and performance in diverse climatic conditions. Additionally, HDPE geomembranes offer low permeability, effectively preventing the migration of liquids and gases.

Applications of High Density Polyethylene Geomembranes

HDPE geomembranes find widespread use in various civil engineering, environmental, and industrial applications. In environmental containment, they serve as liners for landfills, ponds, lagoons, and reservoirs, providing effective barriers against leakage and contamination. HDPE geomembranes are also utilized in wastewater treatment plants, where they line settling ponds, anaerobic lagoons, and sludge dewatering facilities.

In the mining industry, HDPE geomembranes are employed in heap leach pads, tailings impoundments, and acid mine drainage containment systems. Their robust construction and chemical resistance ensure the safe containment of mining by-products and prevent environmental pollution. Additionally, HDPE geomembranes are used in agricultural applications, such as irrigation ponds, manure storage facilities, and silage pits, where they help manage water resources and protect soil quality.

Conclusion

In conclusion, geomembranes play a vital role in modern engineering and environmental protection efforts, offering effective containment solutions for liquids and gases. Composite geomembranes, with their multi-layered construction, provide enhanced strength, puncture resistance, and environmental protection. High-density polyethylene geomembranes, known for their durability and chemical resistance, offer reliable containment in diverse applications. Whether in landfill liners, mining operations, or wastewater treatment facilities, these geomembranes contribute to sustainable development and environmental stewardship."

- Previous:Is geomembrane permeable?

- Next:How is geomembrane manufactured?

-

2024-06-13Geomembrane is not plastic cloth