- Understanding the Role of Geomembrane Liners in Waste Management

- Innovations in Geomembrane Liners for Water Management

- Geomembrane Liners: A Comprehensive Guide

- The Future of Geomembrane Liners in Civil Engineering

- Geomembrane Liners: Enhancing Landfill Stability

Manager:Alvin Wang

WhatsApp:+62 8983806051

Tel:+86 10-5797-1075

Email:steelwang@okorder.com

Address:3rd Floor, No.2 Building, No.1 Sanlihe Road

Which is better CPVC or HDPE geomembrane?

In terms of containment materials, engineers and project stakeholders are often faced with a choice between Chlorinated Polyvinyl Chloride (CPVC) and High-Density Polyethylene (HDPE) geomembrane. Both have unique properties and advantages that make the selection between them an important matter in planning and designing a project. In this article, we seek to compare the CPVC and hdpe Geomembrane to determine which one is more suitable for different containment applications.

Cpvc geomembrane

This geomembrane made from thermoplastic material is derived from polyvinyl chloride (PVC) resin that has been chlorinated in order to enhance its chemical resistance and temperature performance. Known for its excellent chemical resistance, high-temperature tolerance, as well as dimensional stability, CPVC geomembranes are suitable for various containment applications like chemical storage tanks, secondary containment, and industrial lining systems.

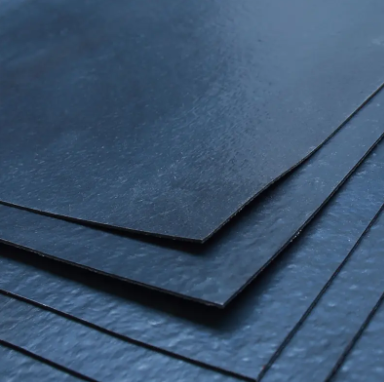

HDPE Geomembrane

However, HDPE geomembrane is a man-made liner produced from high-density polyethylene resin. It boasts good mechanical strength; it is chemically resistant and flexible making it ideal for several containment applications such as landfills, ponds, reservoirs, wastewater treatment facilities among others.

Comparing Properties

Even though both types of membranes share some similarities in terms of their ability to resist chemicals and be impermeable there are marked variations between them concerning their properties and their performances.

Chemical Resistance

Both CPVC geomembrane as well as HDPE geomembrane provide excellent resistance against a variety of substances including acids alkalis solvents hydrocarbons. Because of its chlorine-based structure however CPVC geomembranes may have slightly better chemical resistance towards some aggressive chemicals compared with HDPE geombranes. Nevertheless either material can be used to hold most common chemicals found in industrial settings as well as environmental applications.

Temperature Performance

Another strength of CPVC geomembranes over HDPE geomembranes is their high-temperature resistance. It can withstand temperatures above 200 °F (93°C) making it suitable for applications in which hot liquids or steam are expected. On the other hand, HDPE membranes are strong and tough but soften and deform at higher temperature thereby limiting their use in high temperature environment.

Mechanical Strength

In terms of mechanical strength as well as puncture resistance, HDPE geomembrane outweighs CPVC geomembrane. This means that HDPE geomembrane is less prone to punctures, tears and damage resulting from sharp objects or heavy loads which makes it ideal material for any application where structural integrity matters most. However, CPVC geomembrane may be more susceptible to punctures and mechanical damages because of its softness and greater flexibility when compared to HDPE geomembrane.

Flexibility and Installation

On the other hand, HDPE geomembranes are known for being highly flexible as well being easy to install hence capable of fitting in irregular surfaces while still accommodating ground movement without sacrificing on their performance. Nevertheless, CPVC geomembrane might be more difficult to conform than an equivalent thickness of certain polyethylene membrane especially at low temperature. Despite this fact however, it offers some advantages over the HDPE material with respect to ease of welding and seam integrity.

Applications

The choice between CPVC Geomembrane and HDPE Geomembrane depends on specific requirements and conditions of each containment application. Each material has unique properties that make them better suited for particular applications:

CPVC Geomembrane: For cases where high-temperature tolerance and excellent chemical resistance matter most, CPVC geomembranes are perfect materials. The superior performance within increased temperatures make them appropriate for industrial settings involving containment of hot liquids, chemicals or steam thereon.

- HDPE Geomembrane: In cases where there is a need for better tensile strength, durability and resilience, the HDPE geomembrane is usually used. Its good impact resistance and convenient nature makes it useful in diverse containment uses such as landfills, ponds, reservoirs and waste water treatment plants.

Conclusion

In conclusion; whether to use CPVC geomembrane or HDPE geomembrane will depend on the specific requirements and conditions of containment applications. Nonetheless, CPVC geomembranes have their own merits in terms of high temperature tolerance and chemical resistance while HDPE geomembranes are characterized by mechanical strength, puncture resistance and flexibility. To achieve this goal they must critically appraise performance attributes and appropriateness of each material for its planned use so that engineers can make informed choices about linings of geosynthetic containers to ensure that projects achieve their objective and last for long.

- Previous:Which is better polyethylene or HDPE geomembrane?

- Next:Which is stronger polycarbonate or HDPE geomembrane?

-

2024-12-05Geomembrane Liners: A Comprehensive Guide