- Understanding the Role of Geomembrane Liners in Waste Management

- Innovations in Geomembrane Liners for Water Management

- Geomembrane Liners: A Comprehensive Guide

- The Future of Geomembrane Liners in Civil Engineering

- Geomembrane Liners: Enhancing Landfill Stability

Manager:Alvin Wang

WhatsApp:+62 8983806051

Tel:+86 10-5797-1075

Email:steelwang@okorder.com

Address:3rd Floor, No.2 Building, No.1 Sanlihe Road

Which is stronger polycarbonate or HDPE geomembrane?

When it comes to selecting materials for different uses, one of the most critical factors that must be considered is strength. In containment and lining systems, engineers and project stakeholders often have an argument about whether to use polycarbonate material or High-Density Polyethylene (HDPE) geomembrane. Each of these materials has unique features and advantages but determining which among them is stronger ensures that the selected material will last long enough while being used reliably. This paper compares polycarbonate and hdpe Geomembrane to establish which of the two serves as a stronger material for various applications.

Understanding Polycarbonate

Polycarbonate is a transparent thermoplastic material which has remarkable strength, high impact resistance, and excellent optical clarity. It is typically found in applications which require transparency together with high impact resistant properties such as bulletproof windows, safety glasses and greenhouse panels. Additionally, some containment applications use polycarbonate with an emphasis on clarity and strength.

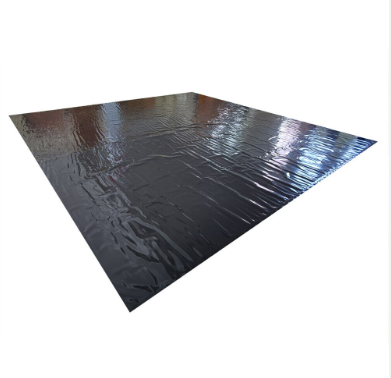

Understanding HDPE Geomembrane

On the other hand, HDPE geomembrane is a synthetic liner manufactured from high-density polyethylene resin. The durability flexibility and impermeability make HDPE geomembranes suitable for various containment applications such as landfills, ponds reservoirs, wastewater treatment facilities etc. This product offers excellent puncture resistance tear resistance UV degradation making it suitable for demanding environmental and industrial application.

Comparing Strength

Strength involves multiple dimensions including tensile strength fracture toughness structural integrity etc.. Therefore let us compare between polycarbonates and HDPEs thus;

1. Tensile Strength

It refers to maximum force that can be tolerated by a substance before it breaks when stretched or pulled out of shape.As compared to polycarbonate,HDP geomembranes usually possess immense tensile strength.Structural integrity as well as stretch resistance are crucial in many cases where considerable tensile forces have to be withstood without changes in shape or rupture occurred and HDPE geomembranes are able to face this kind of loading.

2. Impact Resistance

It is the ability of a material not to crack or break when subjected to sudden blows or impacts. However, although having an excellent impact resistance property, HDPE geomembrane still demonstrates considerable impact resistance. HDPE geomembranes can absorb and dissipate energy from impacts thereby minimizing chances of punctures/torn linings in containment applications which are heavily loaded or contain sharp objects.

3. Flexural Strength

It is the strength that bending materials possess before they break. Polycarbonate has higher flexural strength compared to HDPE geomembrane because it is rigid and stiff. Polycarbonate panels do not crack since they can withstand bending as well as deflection making them applicable in constructions such as roofing, glazing and architectural panels which are structural in nature.

4. Structural Integrity

Structural integrity refers to the ability of a material to retain its shape and properties under different environmental conditions and stresses.HDPE geomembrane possesses an excellent structural integrity even against harsh environmental factors like chemicals, UV rays as well as temperature fluctuations.Polycarbonate too shows good structural integrity but it may be affected after long exposure due to extreme temperatures and UV radiation.

Applications

The choice between polycarbonate and HDPE geomembrane will depend on specific requirements unique for each case. There are advantages associated with both materials that make them more preferable for some uses:

Polycarbonates: These transparent polymers are used where transparency, high-impact resistance, rigidity etc., must be considered foremostly e.g., safety glazing, protective shields for equipment etc (Strydom et al., 2010).

- HDPE Geomembrane: High Density Polyethylene (HDPE) geomembranes are usually preferred in applications where toughness, freedom of movement and being waterproof are highly demanded such as containment liners for landfills, ponds, reservoirs, and wastewater treatment plants.

In conclusion

To conclude, whether to use polycarbonate or HDPE geomembrane depends on the specific strength requirement and conditions of the application. While possessing excellent impact resistance and stiffness attributes over polycarbonate, HDPE geomembrane has better tensile strength characteristics coupled with flexibility and durability. Hence by critically considering the mode of strength and applicability between materials before their usage in a given task can enable engineers and stakeholders knows what they should do to ensure that containment and lining systems will remain efficient for a long period.

-

2024-12-05Geomembrane Liners: A Comprehensive Guide